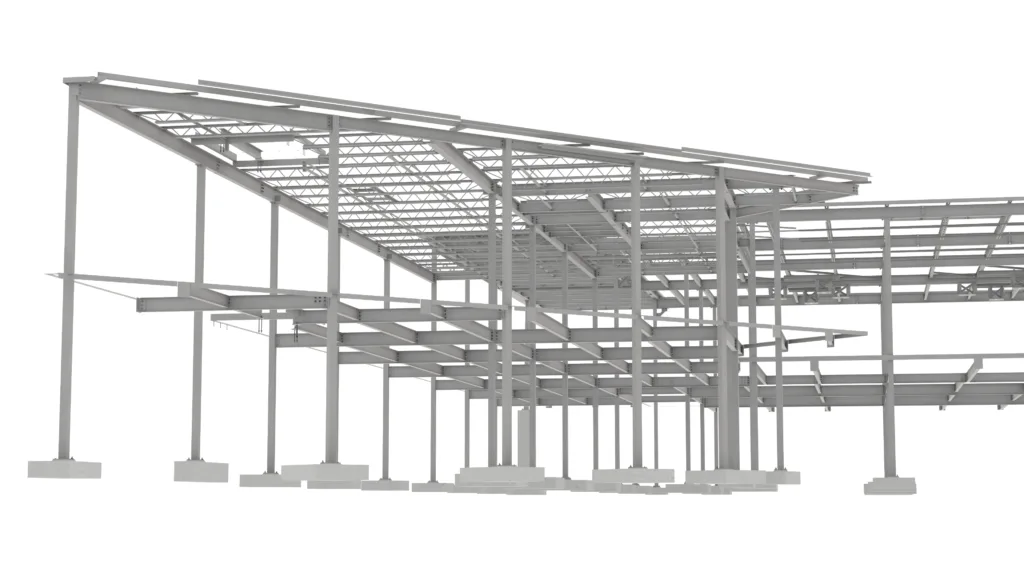

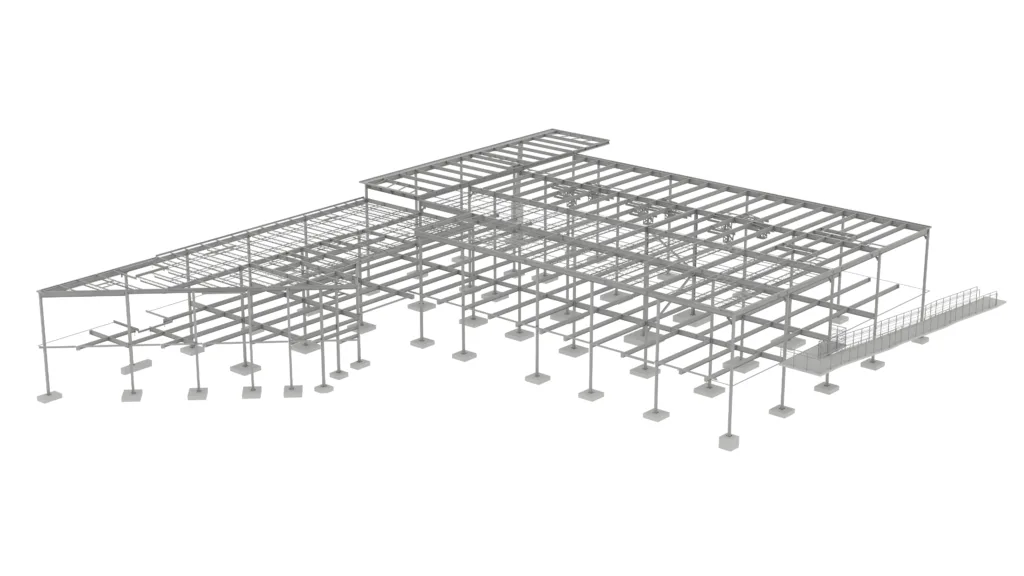

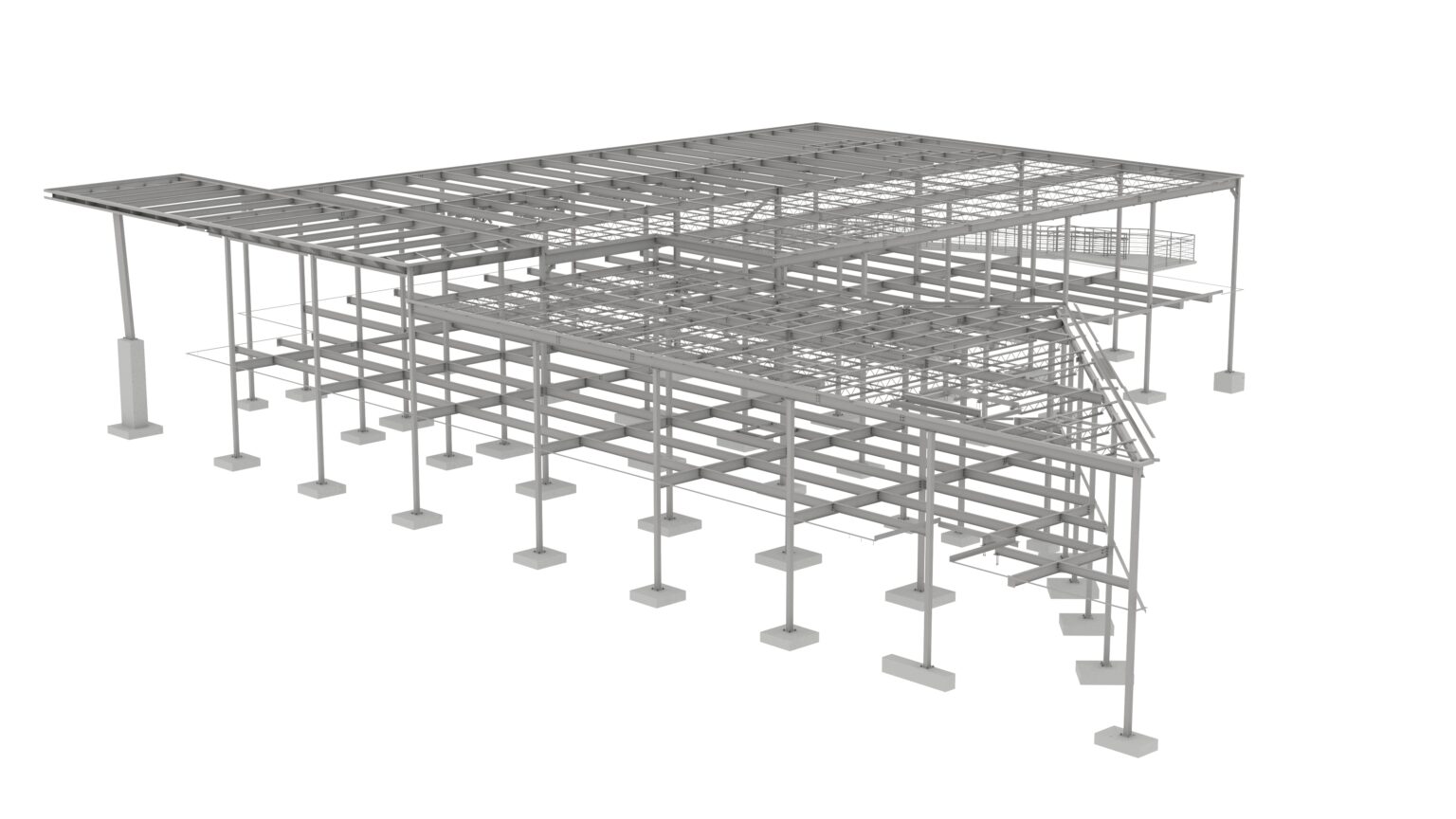

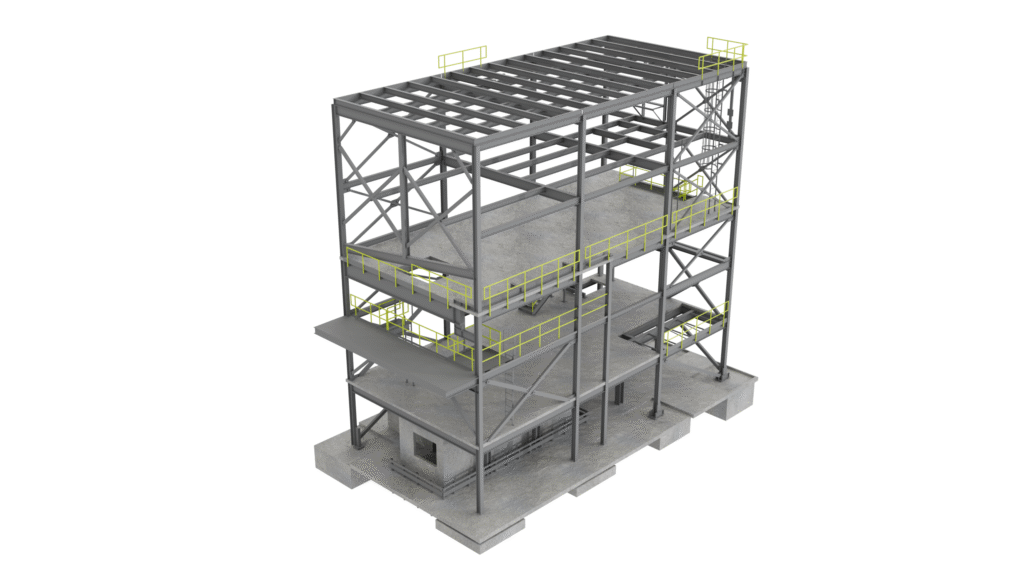

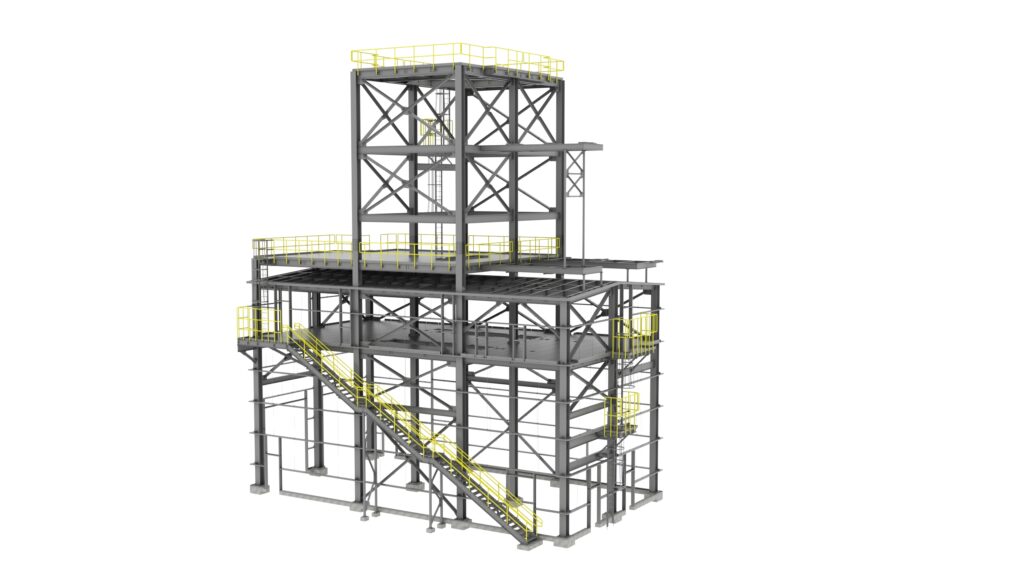

Steel detailing for healthcare facilities plays a crucial role in keeping projects accurate and on schedule. In this hospital expansion project, our team delivered a complete package of structural steel shop drawings, including columns, beams, bearing plates, lintels, hoist beams, bridging steel, and various miscellaneous supports.

As the project progressed, additional elements, including 15 new equipment supports, were added to the scope. Combined with conflicting dimensions and late design revisions, this created a high risk of rework and delays. We took a proactive approach—resolving RFIs early, adapting to changes quickly, and providing phased releases to keep fabrication on track.

The Challenge

Healthcare construction projects come with unique coordination requirements, and this one was no exception:

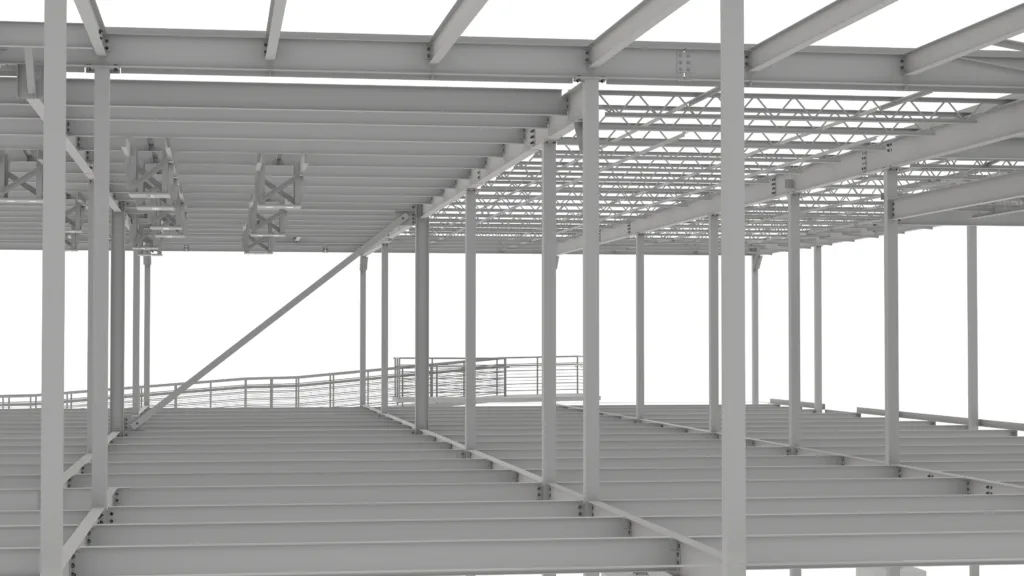

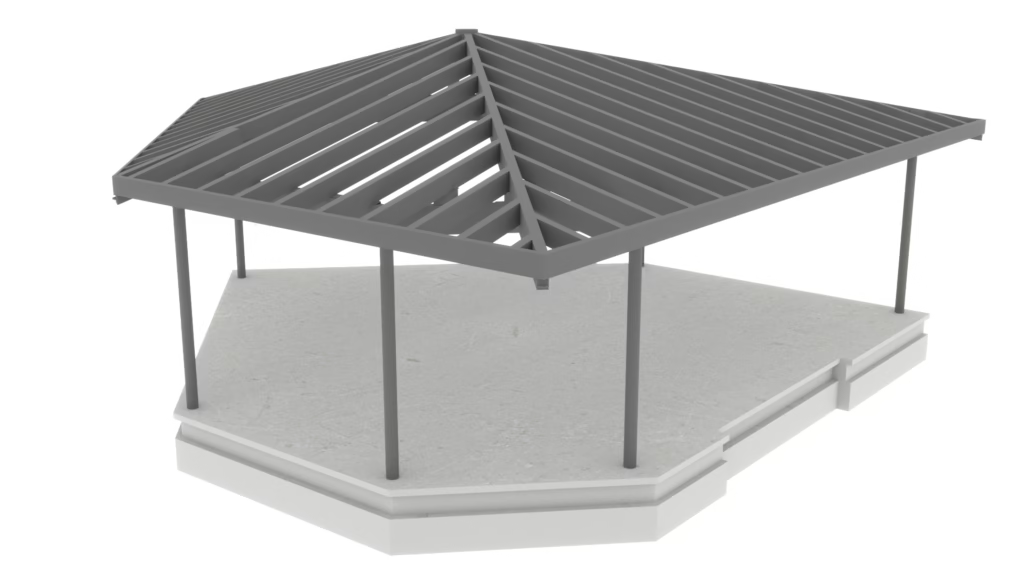

- Custom medical facility steel structures, such as hoist beams, bridging steel, and surgical light supports, required coordination, precise fit, and alignment.

- Conflicting dimensions between architectural and structural drawings made it unclear which information to follow.

- Late updates to joist drawings required modifications to assemblies that had already been released.

Without the right approach, these issues could have caused delays, field fixes, and backcharges for both the fabricator and the contractor.

Our Expertise

We implemented a detailing workflow specifically designed to handle projects where information changes frequently and precision is critical:

- Submitted early RFIs to clarify loads, dimensions, and scope responsibilities before issuing drawings.

- Provided phased releases of structural steel shop drawings, ensuring the fabricator always had approved information to work with.

- Integrated all new scope items, such as equipment supports, smoothly into the model and documentation.

This method allowed us to provide healthcare construction steel services that were accurate, timely, and ready for fabrication.

The Result

Our proactive strategy ensured that the project was delivered without errors or delays:

- The project concluded with a fully coordinated steel package and zero rework, providing confidence to the contractor and project team.

- All dimensions were confirmed before fabrication, eliminating the need for shop corrections or field welding.

- Shop drawings were delivered on schedule, even after several design updates.

- Installation on site was seamless, with assemblies fitting as intended.

Ready to Elevate Your Steel Packages?

At ESD Solutions, we don’t just create drawings — we deliver constructible fabrication packages that streamline your schedule and minimize installation risks.

Let’s build it right the first time. Reach out to ESD Solutions and get detailing that delivers.