At first glance, hiring freelancers for steel detailing seems like an easy way to save money and handle extra workload. Freelancers can be cheaper than detailing companies, quick to onboard, and flexible when you only need help for specific projects.

However, the reality is often more complicated. Many fabricators and general contractors discover that the risks of working with freelancers can quickly outweigh the benefits. Missed deadlines, poor-quality drawings, and endless RFIs can erode any cost savings and create stress for everyone involved.

This article explores the real pros and cons of working with freelancers in steel detailing. It also highlights common pitfalls to avoid, red flags to watch out for, and a practical checklist to help you choose a freelancer if you decide to try it.

Why Some Fabricators Choose Freelancers

Freelancers do have some advantages, which is why they remain appealing to many companies.

One of the main benefits is flexibility. A freelancer can be hired only when needed, allowing you to scale resources up or down depending on project load. There is no need to commit to long-term employment contracts or additional overhead.

Another advantage is cost. Freelancers often charge lower hourly rates compared to established detailing companies, especially if they work from countries with lower labor costs. Finally, freelancers make it easy to engage someone for a specific task or short project without ongoing obligations.

While these benefits sound attractive, they should be weighed carefully against the significant downsides.

The Risks of Hiring Freelancers

Although freelancers can sometimes fill a short-term gap, there are several reasons why relying on them for important projects can backfire:

- Unreliable availability – Freelancers usually work for multiple clients. If a higher-paying or more profitable job becomes available, your project may be delayed.

- Inconsistent quality – Many freelancers lack the experience required for complex projects or knowledge of U.S. codes such as AISC, AWS, ADA, or IBC. This often results in errors, such as incorrect weld symbols or misinterpreted code.

- Data security risks – Sharing project files with unvetted freelancers can expose sensitive information. Unlike detailing companies, freelancers rarely have formal processes to protect client data.

- No backup if something goes wrong – If a freelancer becomes unavailable, takes on another project, or disappears, there is often no one else to complete the work.

- Integration and scalability issues – If your workload grows, you will likely need to hire additional freelancers and coordinate their work yourself to ensure they produce a consistent output. The same problem arises on large projects, where one freelancer cannot deliver everything within tight deadlines. Managing multiple independent contractors often requires extra time to align templates, standards, and deliverables, which adds another layer of complexity for your team.

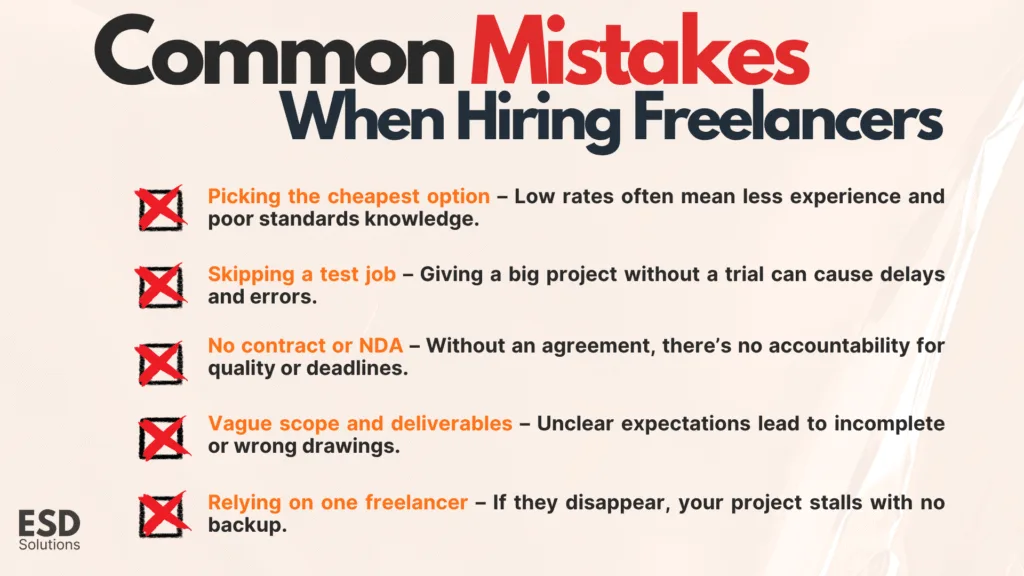

Costly Mistakes Companies Make When Hiring Freelancers

Companies often make the same mistakes when hiring freelancers for steel detailing, especially when focusing too much on saving money upfront. The most common pitfalls include:

- Choosing solely based on price – The cheapest option is rarely the best. Lower rates often mean less experience and weaker knowledge of required standards.

- Skipping a trial project – Assigning a large, complex job without testing a freelancer on a smaller task first can lead to serious delays and quality issues.

- Not using contracts or NDAs – Without a written agreement, there is no accountability for missed deadlines, poor-quality work, or mishandling of project data.

- Lack of clear scope and deliverables – If expectations are not defined upfront, freelancers may submit incomplete or incorrect drawings, or fail to provide the right file formats.

- Relying on one freelancer for a critical deadline – If that person becomes unavailable, you have no alternative to meet project timelines.

Red Flags to Watch For

When evaluating a freelancer, watch for these warning signs:

- No examples of completed shop or erection drawings, only 3D renders or visual models.

- Unrealistic promises, such as completing a large project in a very short time.

- Refusal to sign an NDA or formal contract.

- Vague or evasive answers when asked about AISC, AWS, or other U.S. standards.

- Slow responses or inconsistent communication early in the process which is often signs of future issues under pressure.

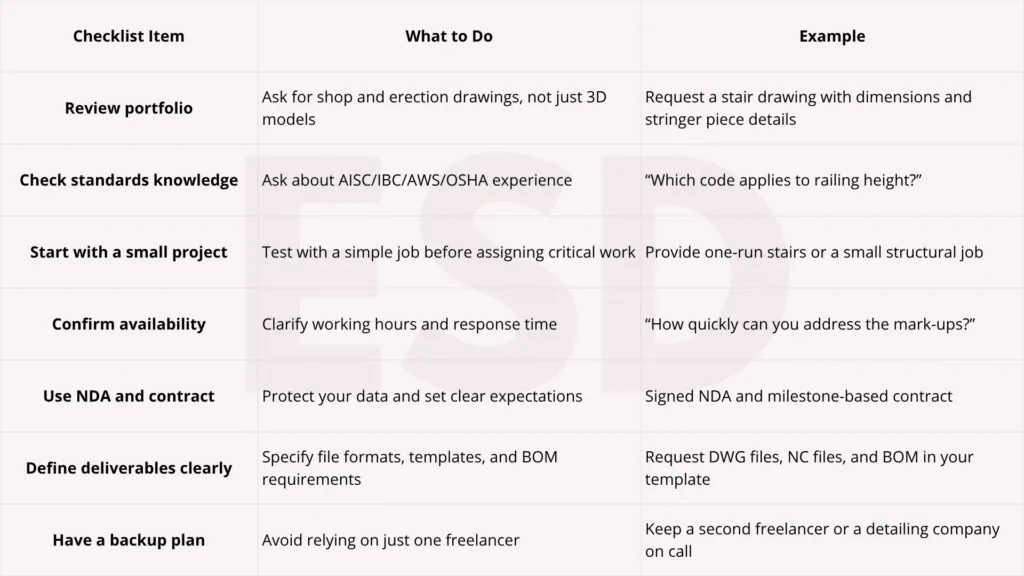

Checklist for Choosing a Freelancer Wisely

If you decide to hire a freelancer, following a structured process can reduce the risks. Below is a practical checklist for selecting the right person:

Why a Detailing Company Is a Safer Option

Professional detailing companies provide resources that freelancers cannot. They have structured QA processes, multiple detailers who can step in if someone is unavailable, and dedicated project managers to ensure deadlines are met. Detailing companies like ESD Solutions, unlike freelancers, provide 100% quality control, strictly follow AISC/AWS standards, and meet deadlines even during peak workloads. Companies are also accountable for their work, meaning they take responsibility for correcting mistakes. By working with a company, you gain consistency in output, workflows, and compliance with standards.

It can be tempting to save money by hiring a freelancer, but one mistake can wipe out those savings and cause additional costs. The potential for errors, delays, and miscommunication is far higher when working with an individual rather than a team.

Making the Smart Choice for Your Next Project

Hiring freelancers for steel detailing can sometimes work for small, low-risk projects. But for complex jobs with strict deadlines and high standards, the risks often outweigh the benefits. Freelancers can be unpredictable, may lack knowledge of U.S. codes, and rarely provide the level of accountability and consistency that projects require.

For projects where accuracy, reliability, and proper coordination matter, working with a professional detailing company is usually the safer and more efficient choice.

At ESD Solutions, we have completed over 500 projects across the United States, ranging from custom ornamental steel to large-scale structural packages. Our team follows proven workflows and strict QA processes to deliver accurate, buildable drawings on time.

If you are looking for a dependable detailing partner, contact us to discuss your project or explore our portfolio to see how we have helped fabricators and builders achieve better results.