Complex geometry in steel detailing poses big challenges for fabricators and detailers. Yet, it also highlights the best in design and engineering. Steel structures are impressive, but every fraction of an inch matters. A single mistake can cause delays, extra work, or safety issues.

This article examines the role of complex geometry in steel detailing. It explains why this aspect is difficult. It also shows what fabricators and detailers need to focus on for a successful project.

What Is Complex Geometry in Steel Detailing?

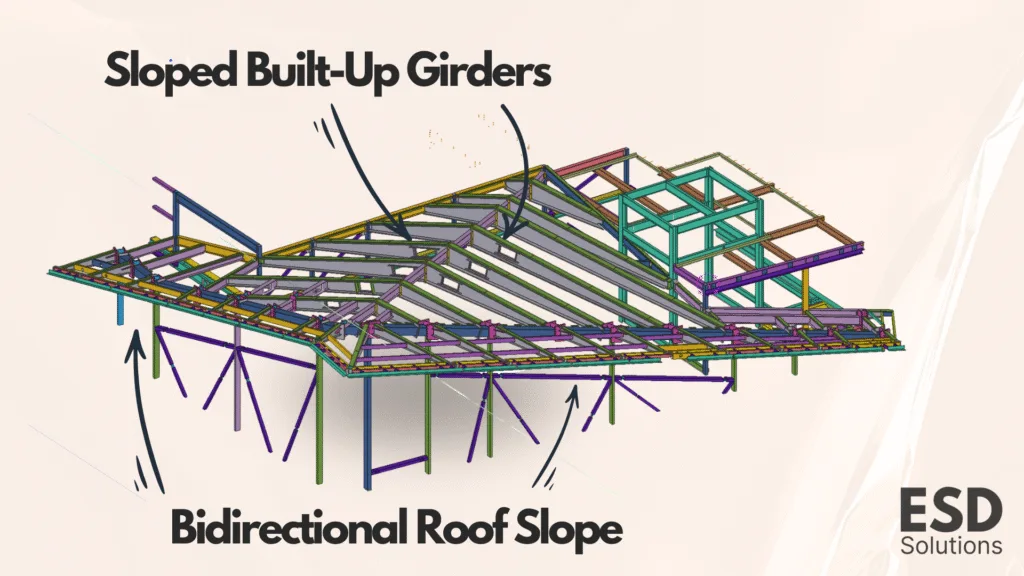

In steel detailing, complex geometry means structures that don’t follow standard right angles, uniform member sizes, or typical connections. It covers a wide range of project types—curved or rolled beams, skewed or sloped bidirectional connections, cambered trusses, and architecturally exposed structural steel (AESS).

For detailers, these projects are fundamentally different. They require customized approaches, highly accurate modeling, and seamless collaboration with engineers, fabricators, and erectors. Unlike standard framing, where most connections are “simple” and repetitive, complex geometry in steel detailing demands unique solutions for almost every member or joint.

Examples of Complex Geometry in Steel Detailing

There’s no such thing as identical steel structures — every single one is unique. Some projects use standard grids and repeat connections. Others need a “personal touch” for almost every member and joint. These are the projects where complex geometry in steel detailing becomes the defining challenge.

Here are some real-world examples showing how diverse and demanding these geometries can be:

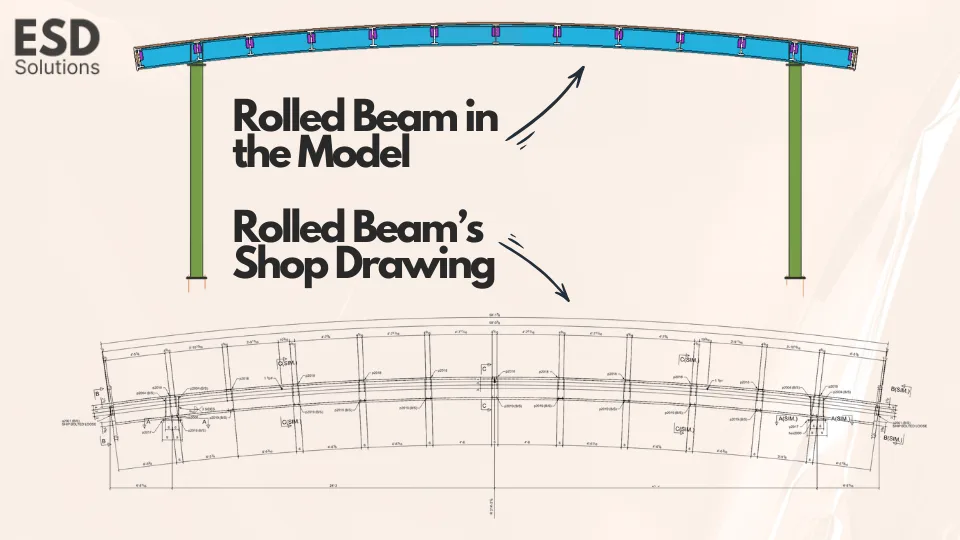

1. Stadium Roofs with Rolled W-Beams

Modern stadiums often use long-span, curved W-beams to achieve sweeping rooflines. Each beam might have a different radius. This means – custom bending templates and specific shop assembly instructions.

- Detailing Implications: Radiused beams make it more complex to model, measure, and fabricate. For example, a detailer has to draw a lot of auxiliary geometry to place the beams along the curved girders correctly.

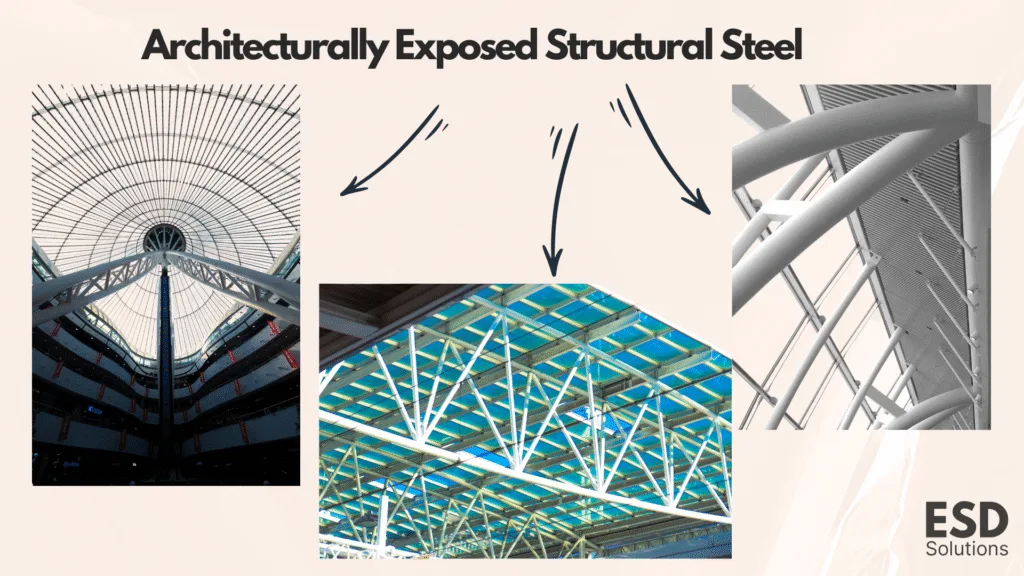

2. Architecturally Exposed Structural Steel (AESS)

Museums, airports, and cultural centers often feature exposed steel as a design element. Every weld, bolt, and cut must meet not only structural requirements but also strict aesthetic criteria.

- Detailing Implications: Welds may need special finishing and grinding. Bolt placement must be carefully coordinated to remain hidden or visually symmetrical. Connections often require custom concealment plates.

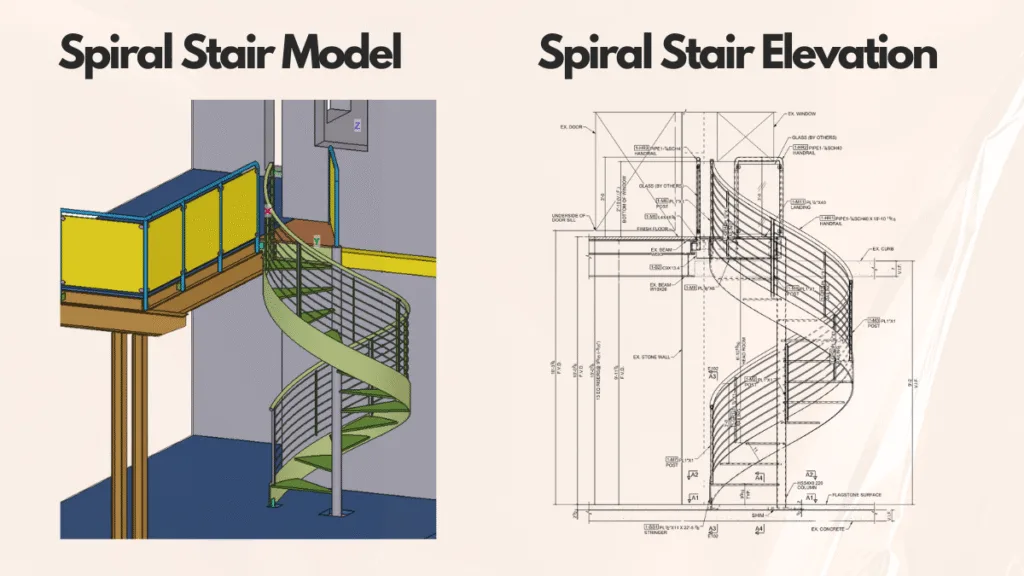

3. Double-Helix or Complex Spiral Staircases

Projects like the “Tornado” staircase at the Fenix Museum demonstrate how spiral staircases with continuously changing radii demand advanced 3D modeling.

- Detailing Implications: Each tread and support requires unique coordinates and tilt angles. Shop drawings must include clear assembly sequences to prevent installation errors.

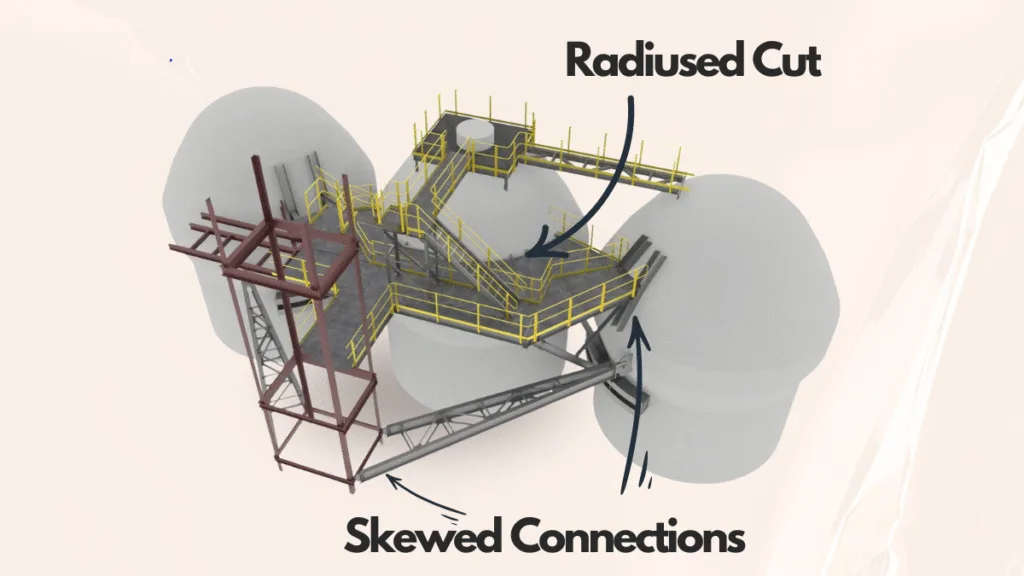

4. Industrial Frames with Skewed Beams

In industrial facilities, access platforms often have beams that frame into columns at angles of 30° to 60°.

- Skewed connections often need custom gusset plates. They may also need slotted bolt holes and special welding methods. These adjustments help meet fabrication & erection tolerances.

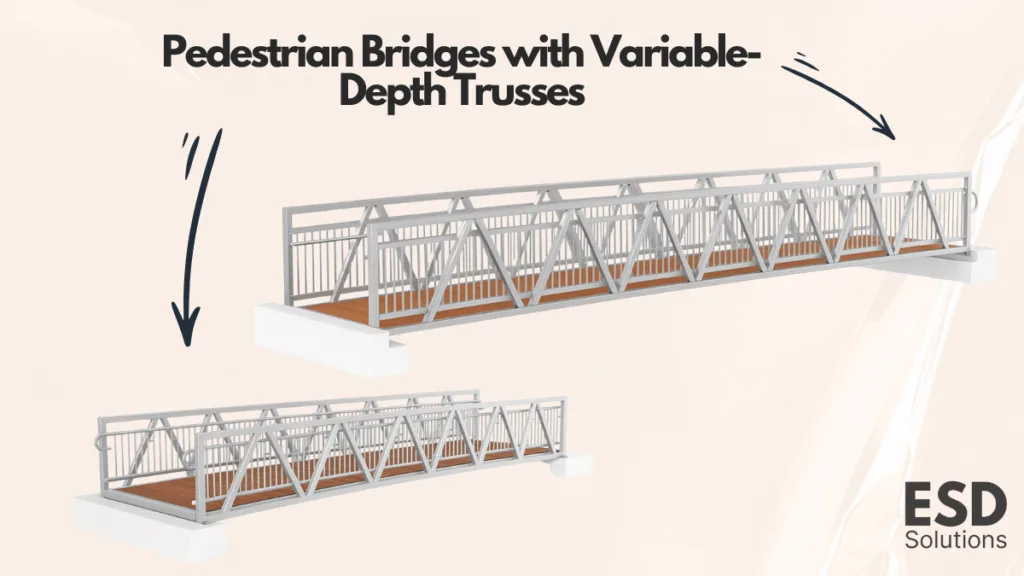

Pedestrian Bridges with Variable-Depth Trusses

Unlike repetitive trusses, bridges with variable panel point elevations eliminate uniformity. No two connections are alike.

- Detailing Implications: Every node requires custom modeling. Parametric detailing automations save time. But each connection still needs a review to ensure it is feasible and accurate.

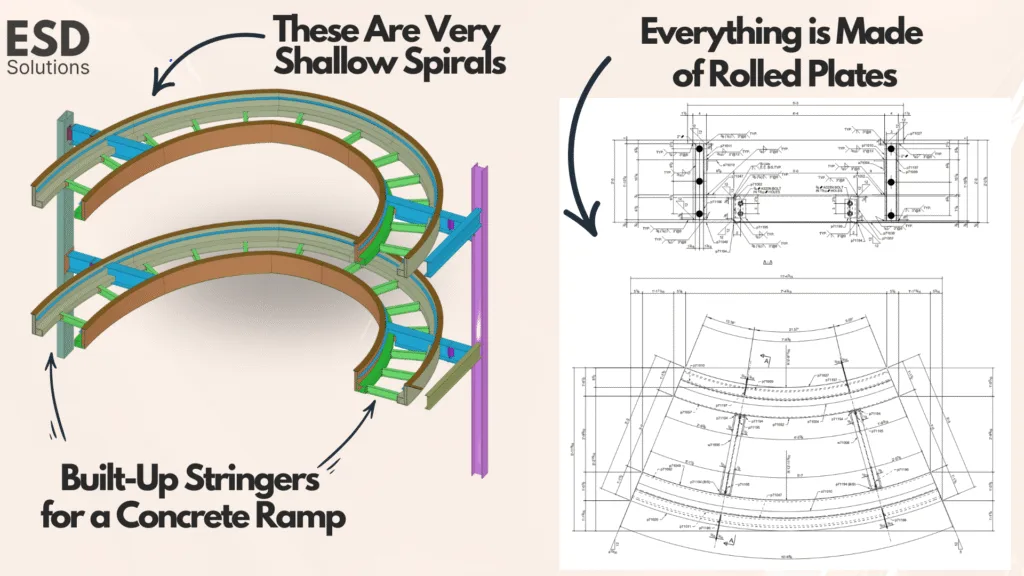

6. Curved Box-Girder & Stringers

Box girders that follow curved layouts are prone to torsion and warping effects.

- Modeling and detailing these elements require advanced techniques. You must define curvature, torsion, and alignment across different planes. Curved box-sections are different from standard profiles. They need to consider warping distortion, complex flange transitions, and uneven support conditions. Frequent design changes from architects, like adjustments in spiral radius or alignment, quickly add to the workload.

These examples show that complex geometry in steel detailing spans many sectors. You can find it in sports arenas, cultural landmarks, bridges, and industrial facilities. Each case requires a tailored approach to ensure both buildability and aesthetic integrity.

Why Complex Geometry in steel detailing Is Challenging

Working with complex geometry in steel detailing poses several risks if not handled properly:

- Extreme accuracy requirements – Even a 1/8 in error can cause significant field-fit problems.

- Incomplete design details – Engineers may leave connection design to fabricators, requiring numerous RFIs.

- Fabrication feasibility issues: Rolled members might be too big for the machine. They may also need extra welded splices.

- Coordination complexity – Many trades must align their models to avoid clashes, especially in BIM settings.

Without the right skills and steps, these risks can lead to delays, more RFIs, and costly fixes in the field.

What Fabricators and Detailers Should Focus On

Handling complex geometry in steel detailing successfully requires a systematic and collaborative approach. Detailers and fabricators should act early in projects to ensure buildable solutions.

1. Early 3D Modeling and Visualization

The team should create a fully constructible 3D Tekla or SDS2 model as soon as possible. This is more than just a schematic—it allows the entire team to see how members, connections, and assemblies will work together.

Early model reviews can spot issues like clashes, impractical links, or fabrication problems. For example, in a recent atrium project, early modeling exposed bolts that would have interfered with the glass façade system. Resolving this in the model saved a lot of rework later.

2. Proactive RFIs and Connection Clarification

Complex projects almost always come with incomplete or ambiguous connection details. Detailers should issue RFIs sooner. They can include marked-up screenshots and views from the model.

This method lets engineers grasp the issue quickly. They can approve it without a long back-and-forth. Every RFI resolved before fabrication is time saved on the shop floor and in the field.

3. Fabrication Feasibility Checks

Even the best-looking design can fail if it can’t be fabricated. Rolled members can exceed shop bending limits. Skewed parts might need extra templates or locators. Some welds may not be practical.

Checking these details before the final drawings go out helps avoid expensive surprises in the shop. Collaboration with the fabricator during this stage is crucial.

4. Phased Drawing Releases

You can go beyond standard sequencing, where a project is issued in planned phases. A practical approach is to release standard, repetitive parts first. This can clip angles, standard shear tabs, or stair treads, repetitive beams that are not going to change. These components are usually easier to detail and fabricate, allowing fabrication to begin early. Meanwhile, more complex assemblies can be finalized without delaying the overall schedule.

This method keeps production on track. It also helps to prevent bottlenecks in key components later in the project.

5. Rigorous QA/QC

A three-step checking process is key to error-free results. First, verify the 3D model. Then, double-check the shop drawings. In projects with irregular shapes, no two parts are the same. This step ensures that every bolt hole, member length, and slope is right.

6. Coordination with Other Trades

Complex geometry often works closely with concrete embeds, glass systems, and mechanical equipment. Regular BIM meetings and shared models help avoid last-minute clashes in the field.

Detailers and fabricators can turn tricky geometry projects into success stories by using these practices.

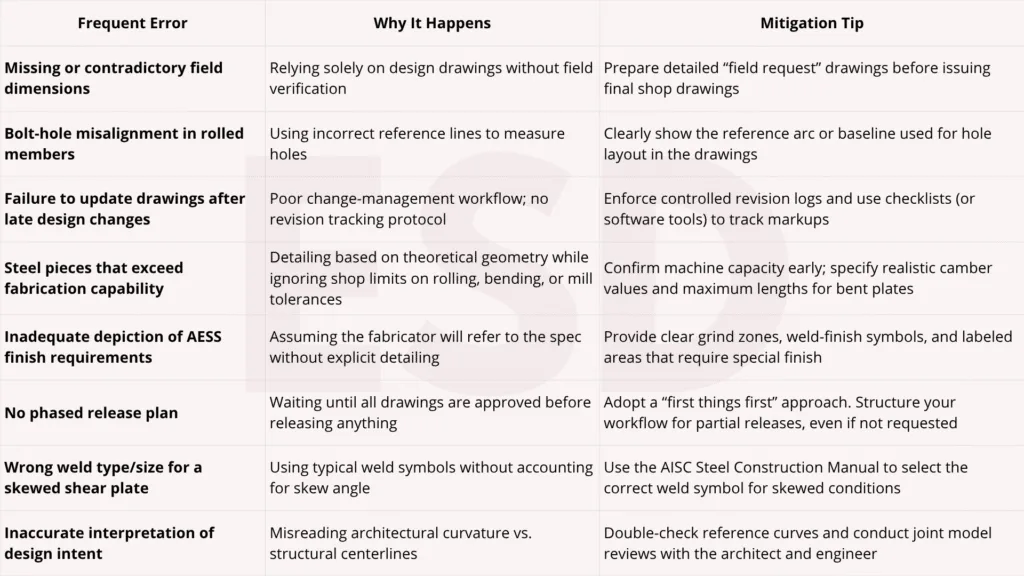

Top Mistakes in Complex Geometry Projects (and How to Avoid Them)

Even with improvements in BIM software and fabrication tech, complex geometry projects still face common mistakes. These errors can delay schedules, inflate costs, or result in embarrassing field fixes. Below are common pitfalls and how to avoid them.

Key Takeaways for Fabricators and GCs

- Complex geometry requires early collaboration. Reviewing constructible models upfront prevents months of rework.

- Proactive detailing saves time. Early RFIs and phased drawing releases keep schedules on track.

- Accuracy is everything. Rigorous QA/QC ensures flawless shop drawings and installation.

When done right, complex geometry in steel detailing is not just a challenge. It’s an opportunity to achieve great results and prove you can get it right the first time.

Ready to Tackle Your Next Complex Project?

At ESD Solutions, we focus on complex geometry in steel detailing. This includes curved staircases, architecturally exposed steel, custom trusses, and irregular structural frames. Our skilled detailers provide precise 3D models, buildable shop drawings, and BIM-ready files. This helps fabricators and GCs stay on track and avoid expensive mistakes.

Have a challenging project ahead? Let’s discuss how to make your next complex design a smooth success. We’ll ensure it’s error-free, on time, on budget, and built correctly the first time.