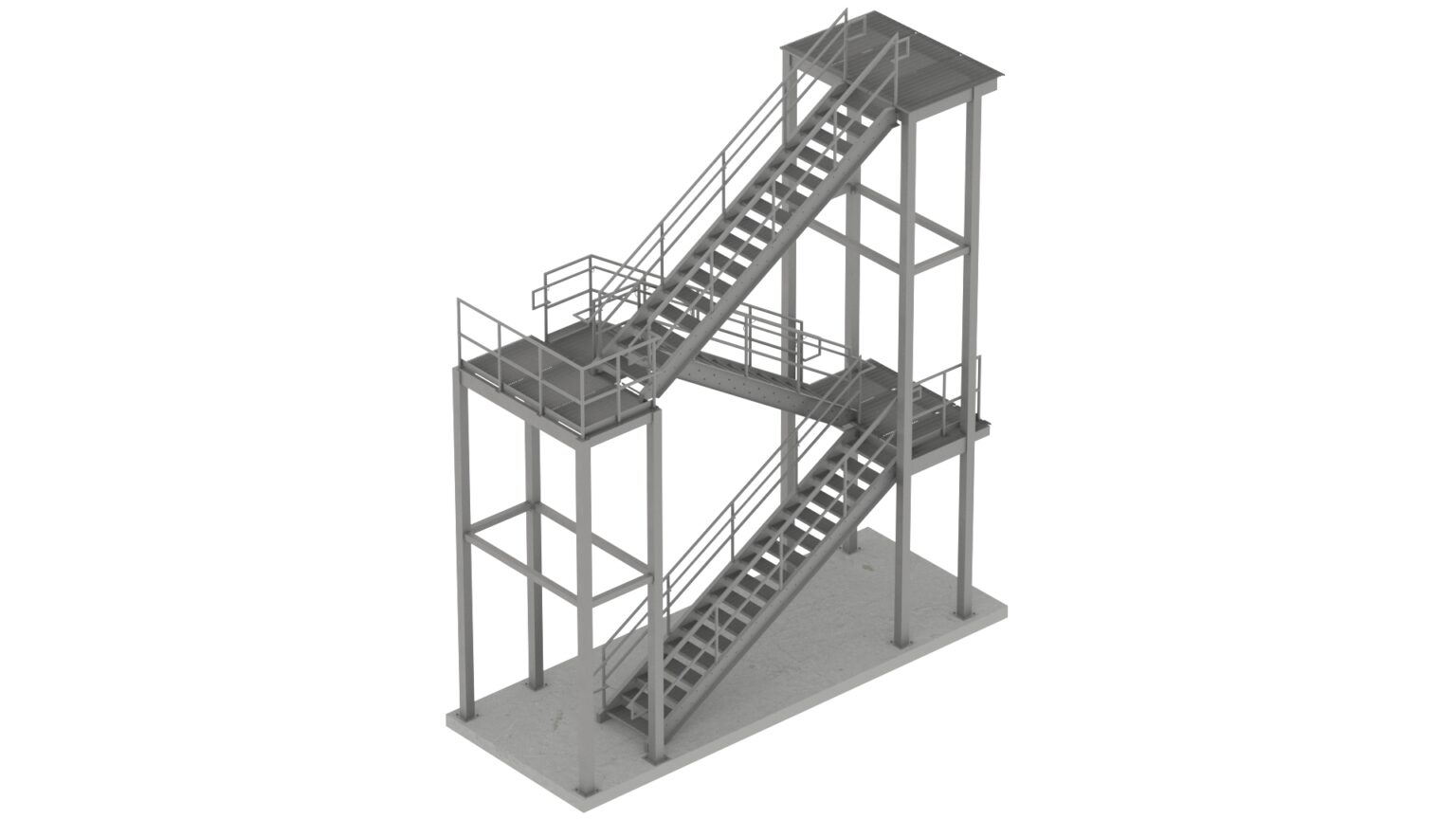

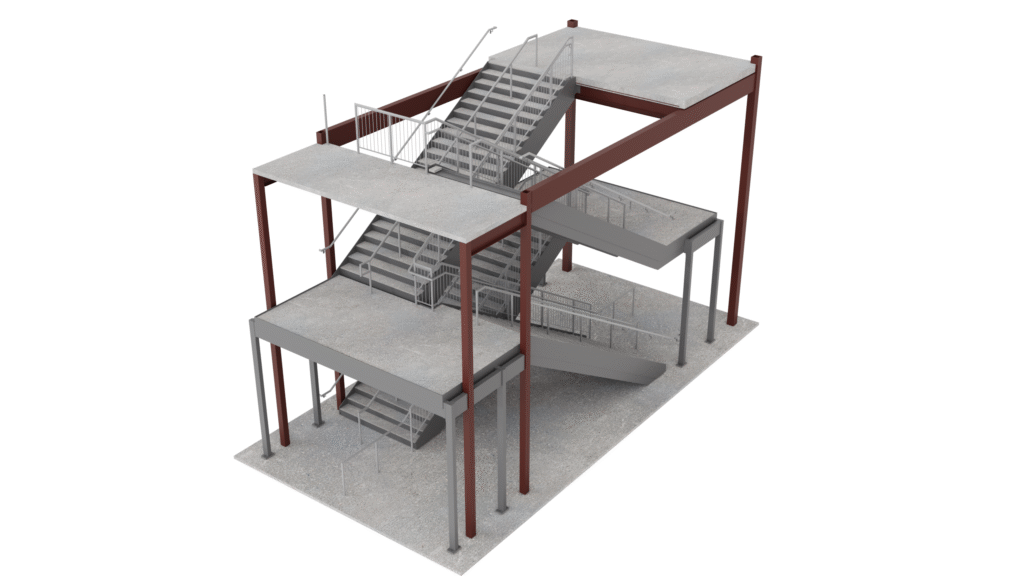

We recently detailed a multi-flight steel stair system with platforms, guardrails, and slip-resistant grating — all designed for code compliance and easy installation.

Our goal? Deliver fabrication-ready shop drawings that could go straight to the shop floor without causing field headaches.

The Challenge

This wasn’t a simple “two-stringers-and-done” job. The drawings revealed multiple challenges that could easily cause delays or rework if not solved in detailing:

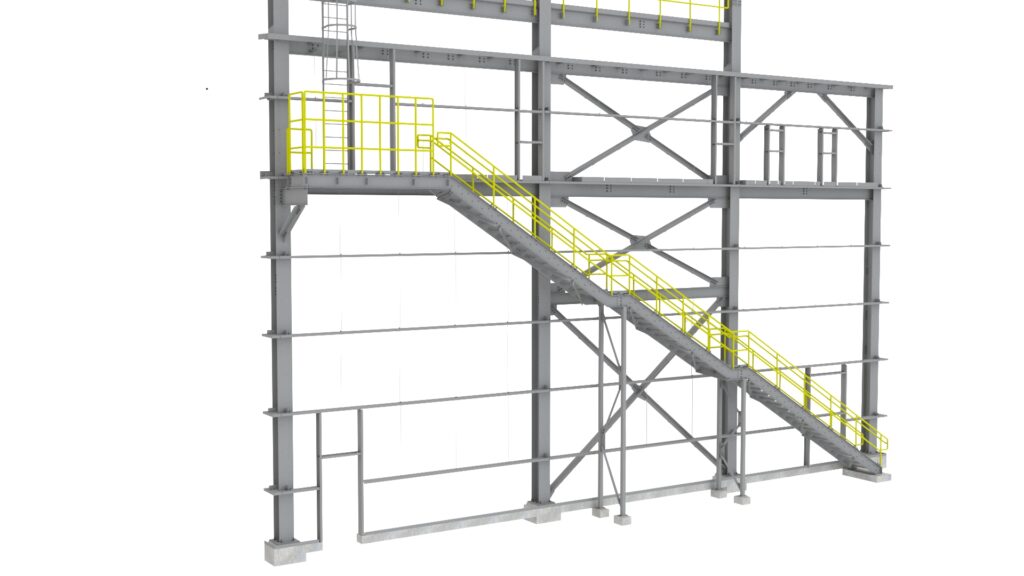

- Multiple elevations — Landings at different elevations meant every stringer cut, tread count, and guardrail termination had to be unique.

- Two tread types — T1 and T2 grating treads had to be integrated without breaking riser uniformity.

- Continuous guardrails — Pipe rails wrapped around flights and landings, requiring precise equal post spacing.

- Heavy HSS framing — HSS10×4, HSS8×4, and HSS6×4 members intersected with C12 stringers — all needing exact copes and weld preps to avoid grinding on-site.

- Custom grating fit — Panels ranged from small (1′-0″ × 2′-4″) to long (over 8′), making precision critical for a clean install.

Our Expertise in Action

To make this stair 100% buildable before fabrication, we:

- Modeled everything in 3D — From C12 stringers to HSS frames, grating, and guardrails, every hole, cope, and weld detail matched fabrication standards.

- Coordinated every elevation — Ensured each landing, tread run, and guardrail aligned with existing as-built conditions.

- Perfected tread & grating layouts — Checked nosing lines, riser heights, and ADA compliance before releasing shop drawings.

- Verified guardrail geometry — Aligned post locations and pipe slopes for a seamless transition between flights and landings.

- Detailed HSS intersections — Eliminated field fit-up issues with precise cut lists and weld callouts.

- Provided CNC-ready files — NC and DXF files matched fabrication tolerances, avoiding field cutting.

The Result

The fabricator received a fully coordinated steel stair system package — including shop drawings, erection drawings, and CNC files — ready to fabricate and install without fixes.

The result:

- Zero calls during installation

- No field modifications

- Clean, on-time install that matched the design’s intent and met safety standards

Ready to Elevate Your Steel Packages?

At ESD Solutions, we don’t just create drawings — we deliver constructible fabrication packages that streamline your schedule and minimize installation risks.

Let’s build it right the first time. Reach out to ESD Solutions and get detailing that delivers.