Finding a quality steel detailer isn’t as simple as scrolling through a list of subcontractors and picking the cheapest option. If you’ve ever had to deal with incomplete drawings, endless RFIs, or field crews calling you with urgent questions, you already know that the wrong detailer can cost far more than their initial price tag.

Steel detailing is a crucial step between design and fabrication. A detailer isn’t just “drawing lines.” They’re the link between engineers, fabricators, and erectors. When this link breaks—because of errors, missing details, or poor communication—the entire project suffers.

In this article, we’ll look at why it’s so hard to find reliable steel detailing services, what makes a truly great detailer, red flags to watch for, and how to vet a subcontractor before committing.

Why It’s Hard to Find Reliable Steel Detailing Services

Finding a quality steel detailer isn’t easy — especially in an industry where deadlines are tight, drawings evolve constantly, and fabricators need absolute accuracy. Over the last decade, outsourcing has exploded, and many contractors now struggle to separate reliable detailing partners from low-cost providers who create more problems than they solve.

The Hidden Costs of Low-Cost Offshore Detailing

Offshore detailers often win projects with extremely low pricing, but those savings disappear quickly when quality issues begin to surface. Incomplete callouts, unclear details, missing markups, inconsistent bolt information, and a lack of familiarity with AISC, AWS, or RCSC standards can all cascade into fabrication delays and field confusion.

Shops end up “doing the math” themselves, RFIs multiply, and schedules slip — draining time and budget.

Common Problems Caused by Inexperienced Detailers

Inexperience shows up fast in steel detailing. Common issues include:

- Incorrect weld symbols or missing prequalified weld designations

- Poor bolt spacing, wrong hole tolerances, and clashing components

- No awareness of constructability, leading to unbuildable details

- Ignored client redlines or half-completed revisions

- Unclear shop drawings that force fabricators to guess

When detailers don’t think one step ahead, the shop loses efficiency and the field ends up improvising — the worst-case scenario for any project.

What Makes a Great Steel Detailer

A quality steel detailer is more than just someone who knows Tekla or SDS/2. They’re a partner who understands the practical side of steel construction and proactively prevents issues before they happen.

1. Technical Expertise and Code Compliance

The best detailers have deep knowledge of structural steel detailing, AISC, AWS, and RCSC standards, and local building codes. They know how to prevent common mistakes like:

Incorrect welds for skewed shear tabs.

Missing prequalified weld designations in shop drawings.

Improper bolt spacings or hole tolerances leading to rework in the field.

They also anticipate constructability issues. For example, they’ll ensure welds have enough clearance from bolts, or that connection details can actually be fabricated and installed safely.

When detailers don’t think ahead, the shop ends up improvising, or worse—the field crew is forced to “figure it out.” Neither situation ends well.

2. A Robust QA/QC Process That Catches Mistakes Early

Errors happen when detailers don’t double-check their work. A solid QA/QC in the steel detailing process includes:

- Several-step checking and clash detection.

- Peer reviews to catch mistakes before submittals.

- Maintain clear revision control to prevent outdated drawings from circulating in the shop.

And most importantly: addressing every single redline. There’s nothing more frustrating than marking up drawings, waiting weeks for updates, and finding that only half the corrections were made.

3. Communication That Prevents RFIs

A great detailer asks questions early. They check design intent, clarify gaps, and prevent misunderstandings.

But an excellent detailer does more: they anticipate issues, bring options to the table, and give engineers and fabricators not just questions — but solutions.

This approach reduces RFIs and keeps projects moving. It also builds trust—fabricators appreciate being included in the process instead of just being handed “finished” drawings that don’t work in the real world.

4. Reliability, Accountability, and On-Time Delivery

Freelancers and offshore teams often juggle multiple projects and may pass your work to someone else without telling you. A steel detailing company with in-house staff or a well-managed team can guarantee consistency, deadlines, and accountability.

The difference shows in the results. Reliable detailers deliver on time, without blowing up budgets or forcing crews to scramble.

5. Field-Friendly Shop Drawings Fabricators Love

Detailers should always consider the people who will use their drawings. If an erector has to flip through five sheets to find a single dimension, the detailer didn’t do their job.

Great shop drawings are:

- Easy to read in real field conditions (think sunlight, wind, dirt).

- Precise without being cluttered.

- Self-contained, so fabricators don’t need to reference multiple sheets.

As one fabricator said: “The shop’s job isn’t to crunch numbers—that’s the detailer’s job. Our job is to produce.”

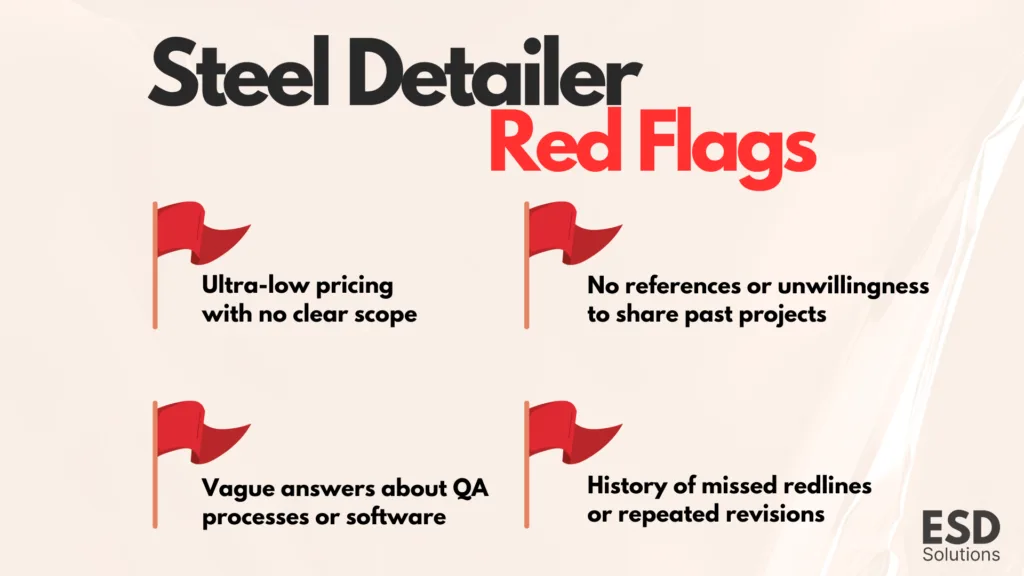

Red Flags to Watch For When Hiring a Steel Detailer

Ultra-low pricing with no clear scope. If it sounds too good to be true, it usually is.

No references or unwillingness to share past projects. Reliable detailers are proud of their work.

Vague answers about QA processes or software. A weak process is a recipe for mistakes.

History of missed redlines or repeated revisions. This is a huge warning sign that they don’t have proper checks in place.

How to Properly Vet a Steel Detailing Subcontractor

Choosing the right detailing partner becomes much easier when you know where to look. A solid vetting process helps you avoid costly mistakes and identify detailers who can genuinely support your schedule, budget, and field teams.

Review Their Samples and Drawing Quality

Ask for real project deliverables — not polished portfolio shots. Review shop drawings, erection plans, stair packages, anchor layouts, and connection details to get a true sense of their competence.

As you review, focus on how usable the drawings are:

- Are dimensions, notes, and section cuts clear at a glance?

- Do sheets follow a consistent logic, or does every page feel different?

- Are welds, bolts, elevations, and references fully defined, or are critical pieces missing?

- Would your fabricators and field crews understand the drawings without guesswork?

Strong work looks clean, coordinated, and self-explanatory.

Weak work forces the shop to reverse-engineer the detailer’s intent.

Ask Questions About QA, Workflow, and Team Structure

A trustworthy detailer can explain exactly how they produce consistent results.

Topics worth exploring:

- Checking process: Who reviews drawings, and what do they look for? Is there a structured approach or just a quick skim before submittal?

- Revision control: Do they track changes, issue clear updates, and prevent outdated sheets from circulating?

- Team transparency: Is the work done by their own staff, or is it quietly subcontracted to a third party?

- Communication style: Do they raise design issues early and propose solutions, or do they send vague RFIs at the last minute?

Clear, confident answers usually signal mature processes. Evasive or inconsistent explanations are a warning sign.

Check References and Past Performance

Client feedback reveals what drawings can’t. Instead of going through a checklist, ask open-ended questions:

- “What was it like working with them day to day?”

- “Did they keep your project moving forward?”

- “Did you trust their deadlines?”

- “How did your shop and field crews feel about the drawings?”

Look for patterns — positive or negative.

Long-term clients and repeat work typically indicate a detailer who delivers predictable quality.

Start With a Small Test Project

A pilot scope is the simplest way to see how a detailer performs under real conditions. Choose something manageable but telling — a stair, a small platform, a connection package.

What you’re evaluating here is not just the drawings, but the way they work:

- Do they engage early or wait until issues pile up?

- Are submittals organized and easy to review?

- Do they absorb redlines efficiently?

- Are their timelines realistic and steady?

A good detailer will make the small project feel smooth and predictable.

If a test scope feels chaotic, rushed, or unclear, a larger project will only magnify those problems.

ESD Solutions — Your Partner for Reliable, High-Quality Steel Detailing

At ESD Solutions, we deliver complete, constructible models and shop drawings built on accuracy, coordination, and proactive communication. Our process minimizes RFIs, speeds up approvals, and keeps your fabrication and field crews moving.

If you’re looking for a quality steel detailer who supports your project from start to finish, our team is ready to help.