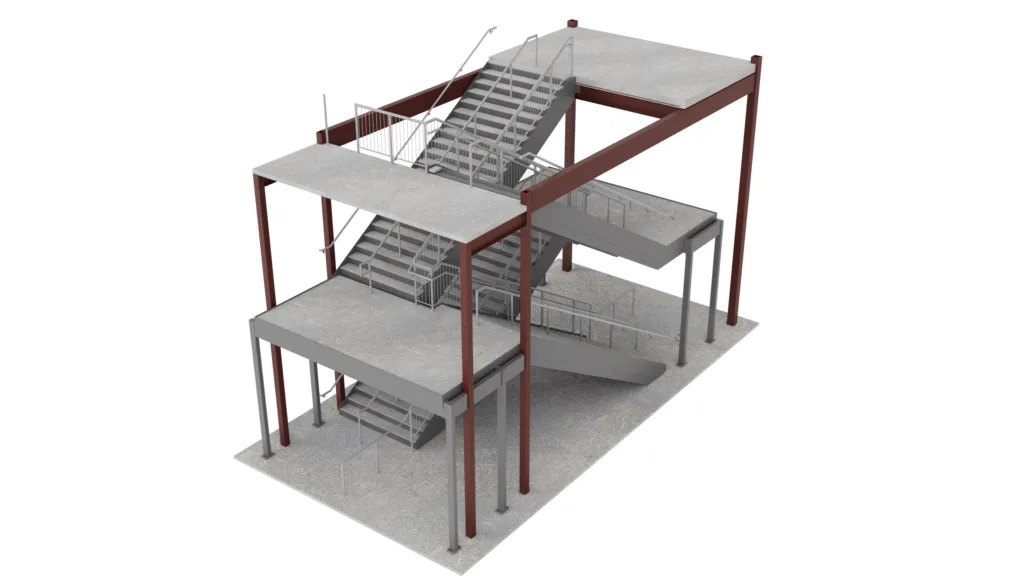

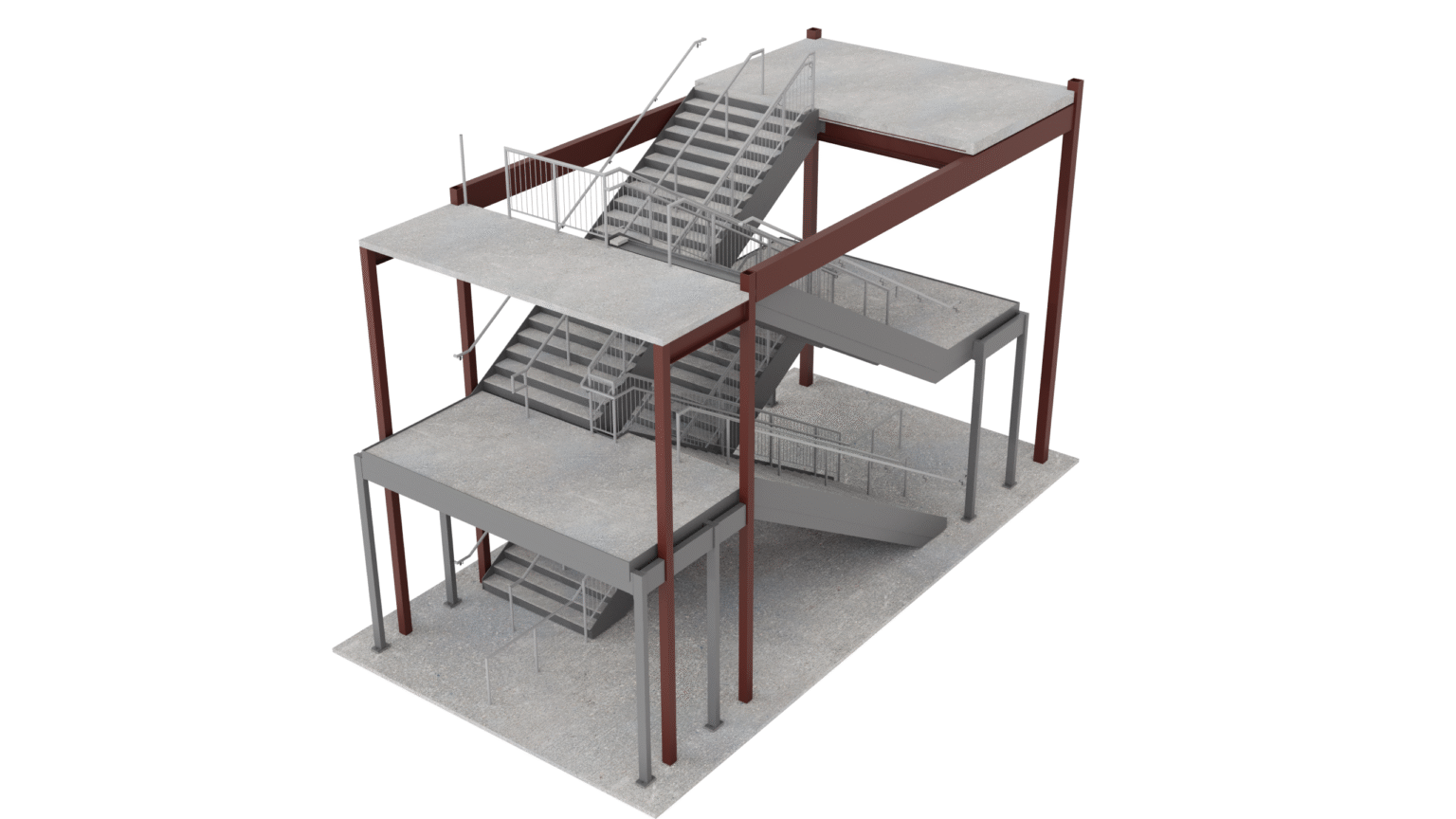

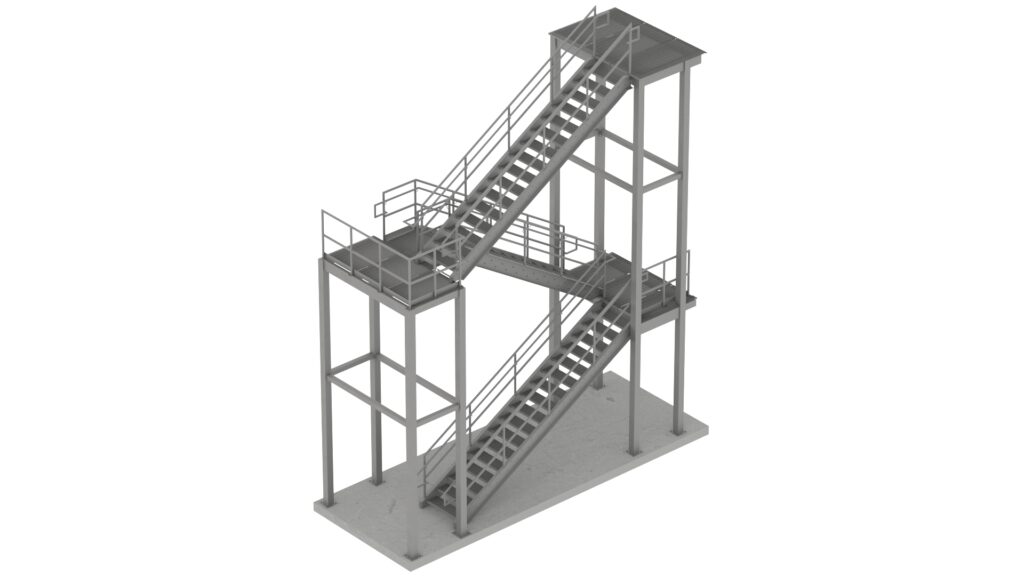

This double-return feature stair was retrofitted into a downtown event center while the venue remained in operation. The design called for an 8′-0″ clear width, concrete-filled pans, and full integration with existing W12×26 framing — all within a narrow 9′-1¼” shaft. We provided a fully coordinated 3D stair model, complete staircase shop drawings, and CNC-ready outputs to streamline fabrication and installation.

Project Challenges

- Changing design criteria – Tread count and landing elevations shifted multiple times through design review.

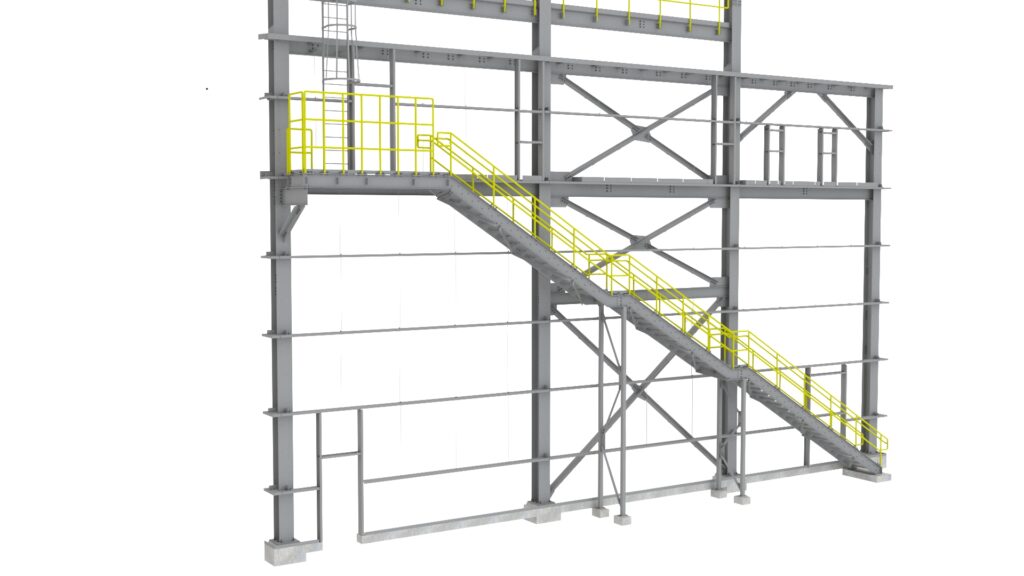

- Existing steel interference – New HSS stringers had to work around active W12×26 beams and fireproofing.

- Tight space constraints – The stair had to fit perfectly between two finished walls with just over 9 ft of shaft width.

- Revised framing requirements – Mid-review, W12 framing was replaced by C6 channels, affecting all connections.

- Anchor and embed validation – Every hardware spec had to be reviewed and approved prior to release.

Our Expertise in Stair Detailing

- Knowledge Accumulation System – Our team utilizes a living library of past project solutions to resolve common issues more quickly and accurately.

- Parametric Stair Templates – We dynamically recalculate tread/riser dimensions and material quantities when the layout changes — even by ⅛″.

- 3D Clash Coordination – We run full interference checks between stair framing, walls, and existing structural steel.

- Anchor Specification Automation – Our internal library pulls in the exact Hilti or Simpson data for each bolt, embed, and baseplate.

The Result

Thanks to tight BIM coordination and clean detailing, the final submittal was approved with no comments. Fabrication began immediately. Two weeks later, the ironworkers flew in both stair flights and completed the install in a single night shift — no cutting, no RFIs, and a final fit within ¹⁄₁₆″.

The end result: a modern, code-compliant 8′-0″ stair with 1½″ Schedule-80 pipe rails that blends seamlessly into the updated conference center lobby.

Ready to Elevate Your Stair Packages?

At ESD Solutions, we don’t just model stairs — we deliver constructible stair fabrication drawings that streamline your schedule and minimize installation risk. Our Knowledge Accumulation System ensures every project benefits from years of proven field experience.

Let’s build it right the first time. Reach out to ESD Solutions and get detailing that delivers.