Steel detailing overhead isn’t just an extra cost—it’s what makes accurate, buildable structures possible. Turning designs into 3D models and shop drawings takes more than a detailer’s time; it requires the right tools, systems, and quality checks to ensure your steel fits the first time and avoids costly field rework.

So if you’ve ever looked at a detailing invoice and wondered, “Why does this cost so much?”—you’re not alone. Where does each dollar actually go when paying for steel detailing services?

This guide will help you understand what you’re really paying for in steel detailing, so you can build with fewer delays, fewer change orders, and less stress.

Steel Detailing Rates

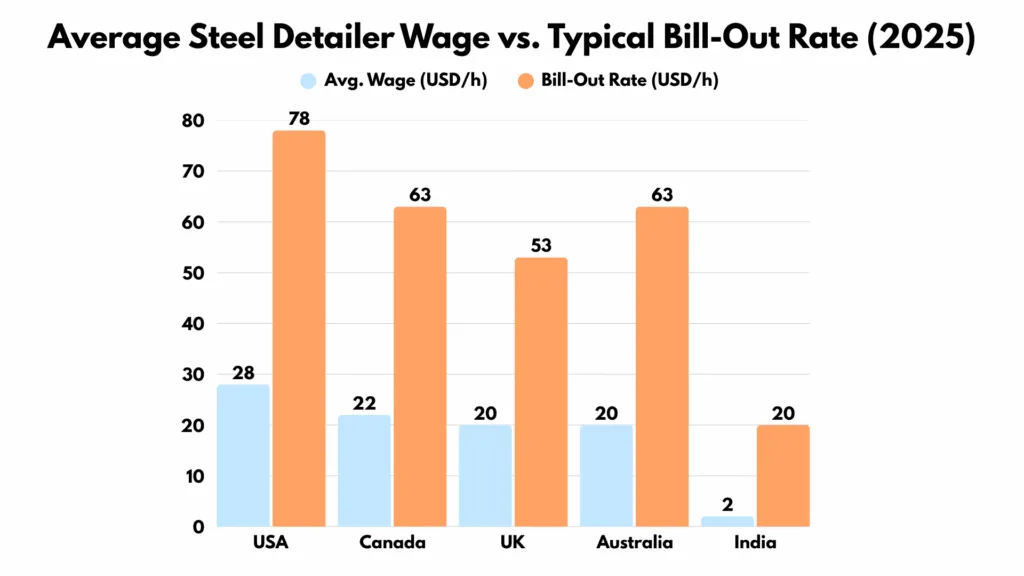

We’ve covered steel detailing rates in-depth in this article, so here’s a quick refresher:

While detailers earn a solid hourly wage—often $25–$28/hour in the U.S.— the rate you pay for steel detailing services includes much more: taxes, licensed software, high-performance workstations, secure IT systems, QA, project management, and the business operations needed to deliver accurate, buildable drawings on time.

Typical client billing rates for steel detailing in 2025 are:

- United States: $80–$100/hour

- Canada: $55–$70/hour

- United Kingdom: $45–$60/hour

- Australia: $55–$70/hour

- India (export): ~$20/hour

These figures are averages, and actual rates vary by company, region, and project complexity.

Understanding Overhead in Steel Detailing

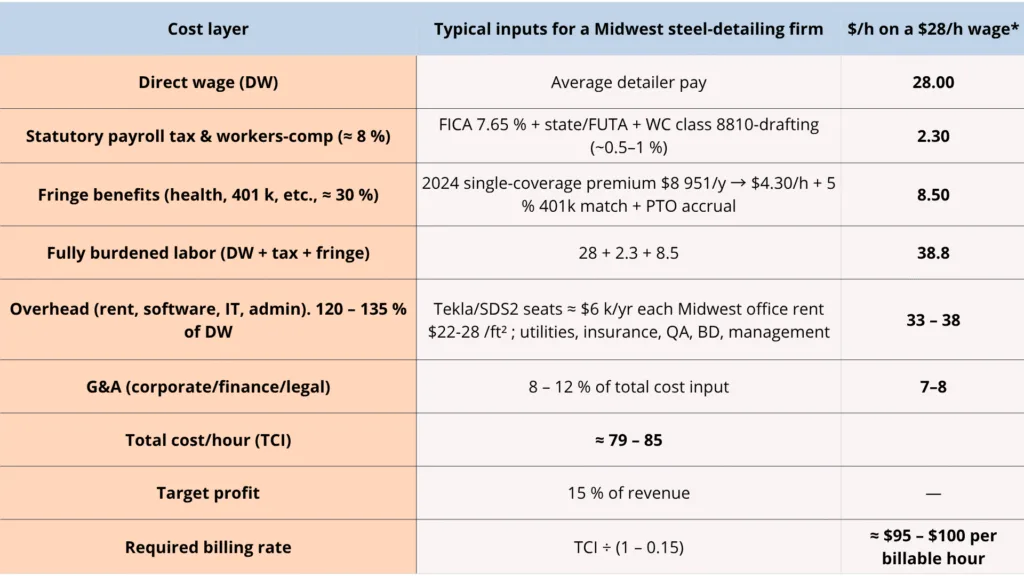

Ever wonder why a detailer earning $28/hour in the U.S. ends up billed to clients at $100/hour?

That gap comes from layers of real, necessary costs that turn a wage into a sustainable, quality-driven service. But let’s be honest: while these costs are essential for accurate steel detailing and dependable delivery, they can strain project budgets if not managed wisely.

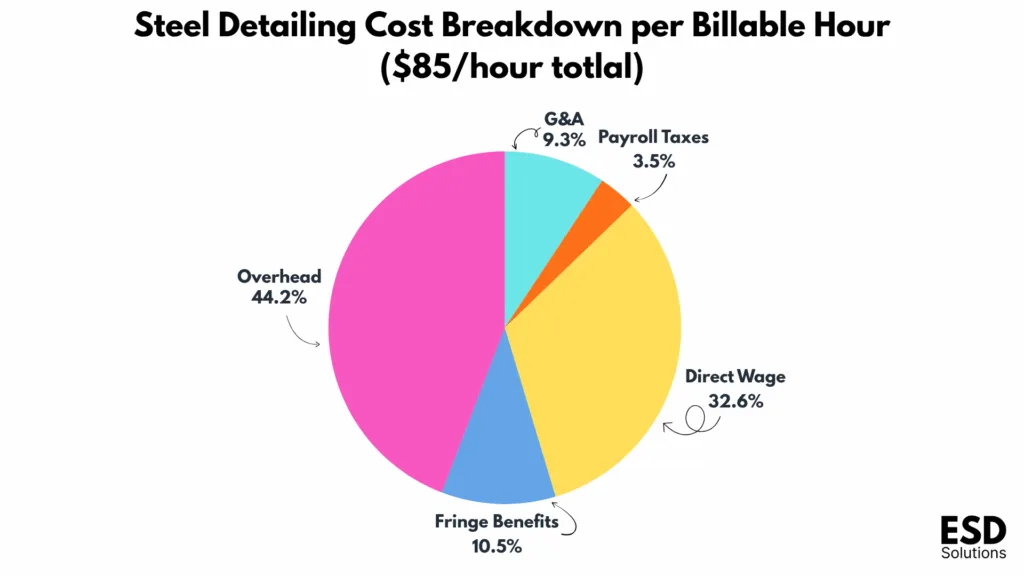

What Does “Cost Per Billable Hour” Actually Include?

In steel detailing, each billable hour covers far more than a detailer’s wage. It funds the tools, systems, and processes needed to deliver fabrication-ready steel models on time while reducing the risk of costly field rework.

Here’s what’s typically included:

- Direct Wage: The base pay for detailers is often around $25-$28/hour for experienced U.S.-based detailers.

- Payroll Taxes and Workers’ Comp: Required contributions like FICA, state unemployment, and workers’ compensation, adding about 8% to the wage.

- Fringe Benefits: Health insurance, 401(k) matching, and PTO accrual, typically adding 10-30% to wages to retain skilled, reliable detailers.

- Overhead:

- Project Management: RFIs, approvals, and coordination with fabricators, engineers, and GCs to keep the project moving.

- Software Licenses: Tekla, SDS/2, Advance Steel, Bluebeam—essential tools averaging $6,000–$7,000/seat/year.

- Hardware and IT: Workstations, servers, backups, and managed IT for secure, fast modeling and drawing workflows.

- Office Space: Rent, utilities, and insurance for a stable working environment.

- QA & Compliance: Senior checkers, redline workflows, and adherence to AISC/AWS standards to catch errors before they become field problems.

- General & Administrative (G&A): Corporate, legal, and accounting functions ensuring consistency, compliance, and accountability on every project.

- Target Profit Margin: A modest 10–15%, needed for sustainability, technology investment, and risk management.

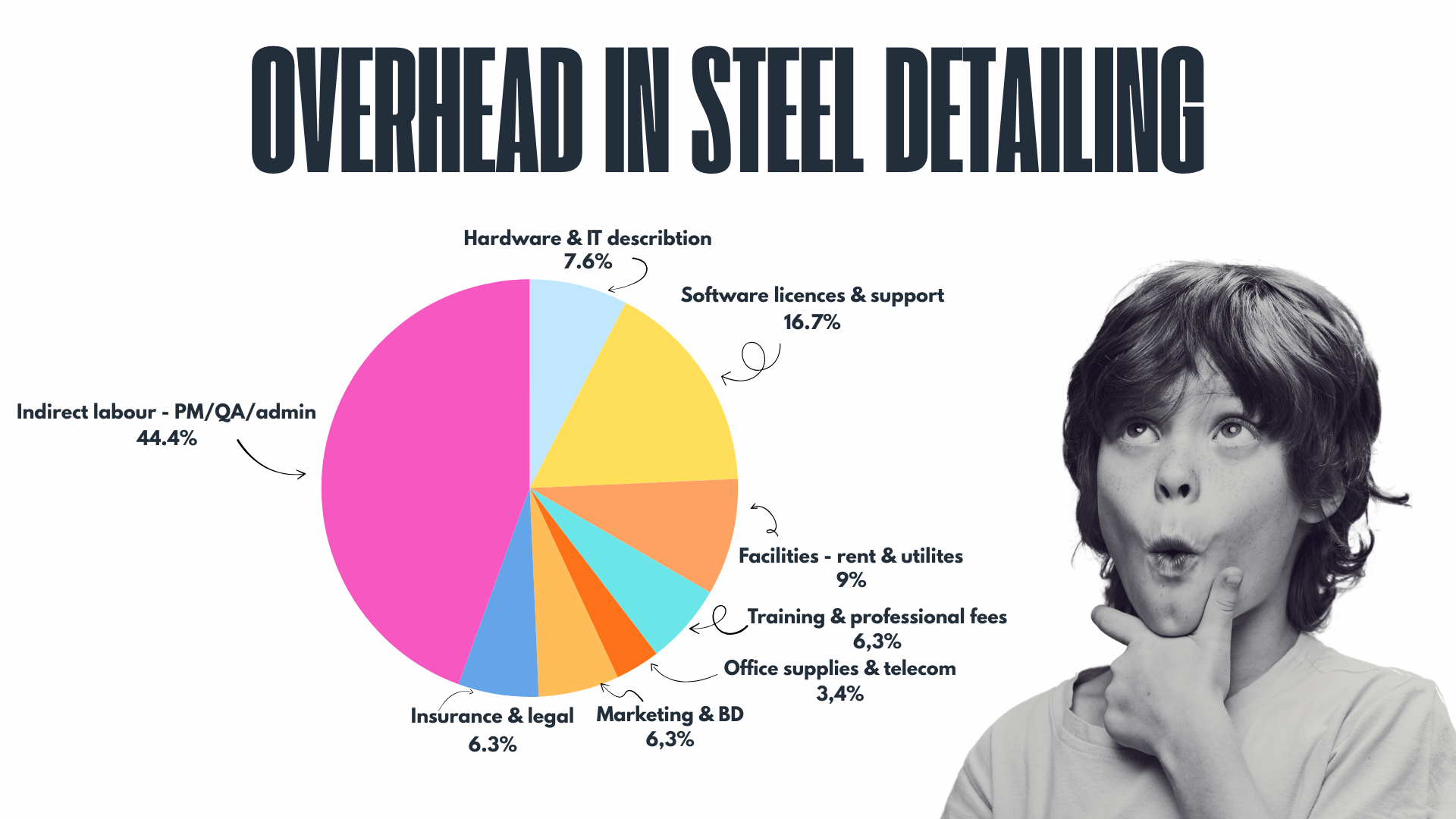

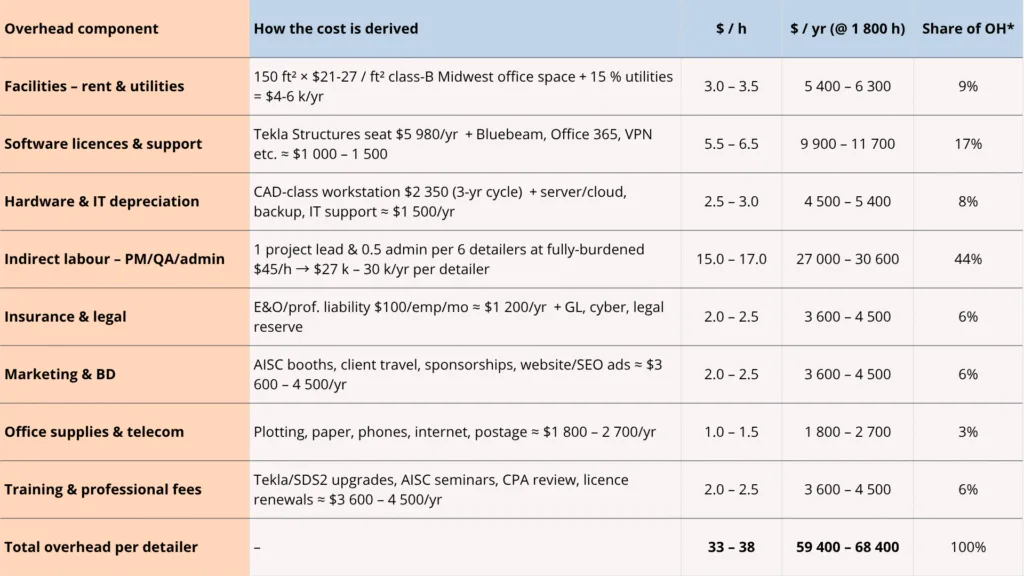

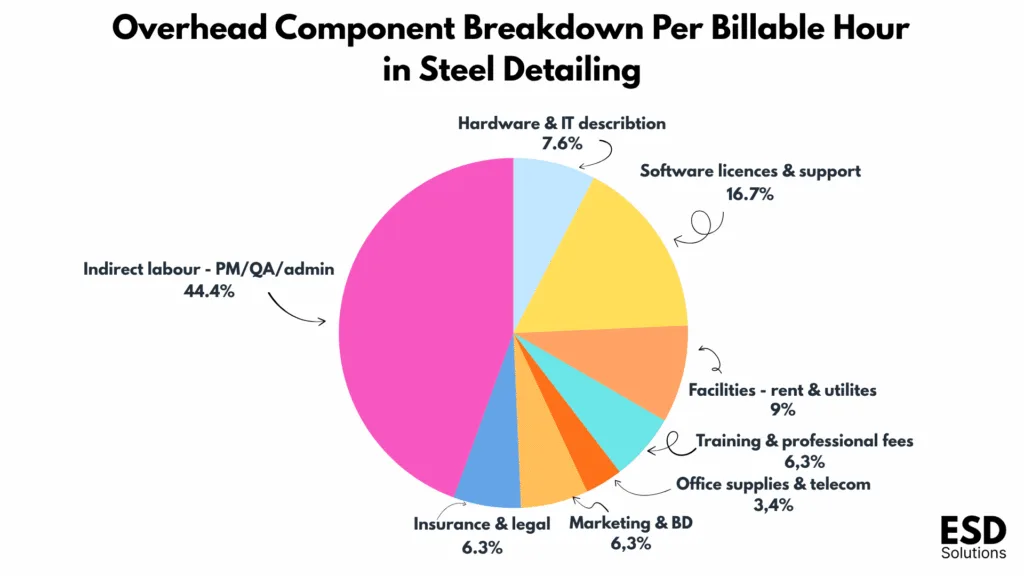

A Closer Look: What Makes Up That Overhead?

Now you may be wondering:

“But what does that $33–38/hour of steel detailing overhead actually pay for?”

Great question. Overhead often feels abstract, but it’s composed of real, measurable expenses that ensure detailed operations are accurate, efficient, and responsive.

To make it clear, we’ve prepared a worked example showing exactly how this $33–38 per billable-hour overhead (≈120% of direct wage) might break down for a typical steel detailing company. (We’ve used a Midwest location as an example to keep the numbers grounded in realistic, market-based costs.)

Why Overhead Isn’t Just “Bloat”

It’s easy to look at overhead as wasted cost, but in steel detailing, it’s what makes quality, speed, and reliability possible.

Here’s what overhead actually enables:

- Reducing Expensive Field Errors: Investing in QA, senior checks, and accurate 3D modeling reduces on-site problems that cost far more than detailing fees. Fixing a beam clash in the model costs minutes; fixing it in the field costs thousands and delays schedules.

- Enabling Fast Turnarounds: Projects move fast, and RFIs and design changes are constant. Overhead covers the IT systems, staffing capacity, and project management needed to handle these changes promptly, so your project isn’t the one stuck waiting.

- Ensuring Quality and Compliance: Licensed software (Tekla, Bluebeam, SDS/2) and trained detailers working to AISC/AWS standards ensure your steel is shop-ready, meets code, and installs as designed, reducing rework and fabrication issues.

- Supporting Project Stakeholders: Overhead allows your detailing partner to coordinate effectively with fabricators, engineers, and field crews, aligning plans with real-world site conditions rather than just drawings on paper.

In short, overhead is what transforms a detailer’s time into a complete, fabrication-ready service that keeps your project on schedule and within budget.

Can Overhead Be Reduced Without Sacrificing Quality?

Yes—but only with intentional strategies that protect reliability while reducing unnecessary costs.

Here are proven ways detailers can reduce overhead while maintaining quality:

Track profit-per-employee rigorously:

Monitor revenue versus cost per employee to identify productivity leaks and non-billable hours that drain the team’s effective rate.

Increase billable hours per year:

Aim for 1,600–1,700 billable hours per detailer by reducing idle time, internal delays, and unnecessary meetings that don’t add client-facing value.

Remote-First Operations:

By operating remotely, firms can eliminate office lease costs, utilities, and commuting overhead while retaining talent and investing in software and QA instead.

Lean out back-office layers:

Firms that keep accounting, IT, HR, and payroll centralized—or share them across a group—reported markedly lower overhead rates.

Selective Outsourcing:

Straightforward scopes like railing jobs, simple structural projects can be outsourced to lower-cost regions while retaining QA and final checking in-house to maintain standards.

Automate repetitive detailing tasks:

Use Tekla macros, model-checking scripts, and parametric modeling to reduce manual editing and avoid repeated low-value tasks.

Reuse internal tools and scripts:

Share spreadsheets, Tekla plug-ins, and Dynamo/Grasshopper scripts across the team to prevent reinventing tools on each project.

These strategies can lower your steel detailing cost while ensuring quality, accuracy, and on-time delivery.

FAQ: Steel Detailing Overhead and Costs

What is steel detailing overhead?

Steel detailing overhead includes all the costs required to deliver accurate, fabrication-ready drawings and models beyond a detailer’s wage. It covers licensed software, high-performance computers, secure IT systems, project management, quality checks, insurance, and the business operations needed to keep your project moving reliably.

How can I reduce steel detailing overhead without sacrificing quality?

Yes — by running remote-first operations, tracking profit-per-employee, outsourcing simple scopes with in-house QA, and automating repetitive tasks. Streamlining admin and reusing internal tools also helps reduce costs while maintaining high detailing standards.

Why does steel detailing cost more than the hourly wage?

The hourly wage for a detailer is only part of the true cost. The final rate you pay also covers payroll taxes, fringe benefits, licensed software, IT infrastructure, project management, QA, and a modest profit margin that keeps the detailing company stable and able to deliver high-quality, reliable work for your projects.

Ready for Smoother Steel Detailing?

At ESD Solutions, we believe that trust starts with transparency. That’s why we’re upfront about how we work, how we price, and how we keep your projects moving without surprises.

In an industry where detailing rates are often questioned, we stand out by showing exactly where value comes from — through accurate, buildable models, open communication, and workflows that prevent costly delays and rework.

Whether you need full project detailing or a reliable partner to meet a tight deadline, you can count on us to deliver with clarity, care, and commitment.

Ready to take the stress out of your detailing process?

Get in touch, and let’s see how we can help your next project run smoother.