Have you ever stopped to think about how steel fabrication in construction makes massive bridges and skyscrapers possible? It’s the process that ensures these structures stand the test of time. But what exactly does that mean, and why is it such a crucial part of the building process? Let’s break it down.

What Do Steel Fabricators Do and What is Structural Steel Fabrication?

Steel fabricators are the skilled professionals who take raw steel—whether it’s metal sheets, hot rolled shapes, or steel plates—and transform it into the structural components that hold everything together in a building or infrastructure.

Imagine it like building with Legos. You start with raw bricks (in this case, steel), and then cut, bend, and connect them to create the structure’s skeleton.

This process involves cutting, shaping, welding, and assembling steel pieces into precise “construction blocks” that fit perfectly during construction. It’s a mix of technology, craftsmanship, and attention to detail that ensures everything aligns just right.

So, when we talk about structural steel fabrication in construction, we’re referring to the entire process of turning raw steel into parts like beams, columns, and frames that are essential to construction projects. These components are carefully crafted to meet the specific requirements of each project.

Why is structural steel so important in construction?

Now, you may wonder why steel is such a go-to material for construction. Steel is incredibly strong and holds up well under pressure. It’s also cost-effective—especially when compared to other materials—and it can be worked with quickly, speeding up the entire construction process. Steel’s versatility allows it to be customized for nearly any design, making it ideal for all kinds of projects, from bridges to skyscrapers.

What’s more, structural steel is relatively lightweight compared to reinforced concrete, yet it doesn’t compromise on strength—thanks to the superior mechanical properties of the material. This makes steel ideal for reducing foundation loads and simplifying transportation and installation.

And let’s not forget—steel is a 100% recyclable material. Steel scrap can be melted down and reused to create new structural components for future buildings, making it a truly sustainable choice in modern construction.

What Does Steel Fabrication Involve?

Steel fabrication in construction is more than just cutting and welding — it’s a carefully coordinated process that transforms raw material into precision-made components ready for installation. Let’s walk through the typical steps that fabricators follow to bring designs to life.

1. Project Kickoff & Detailing

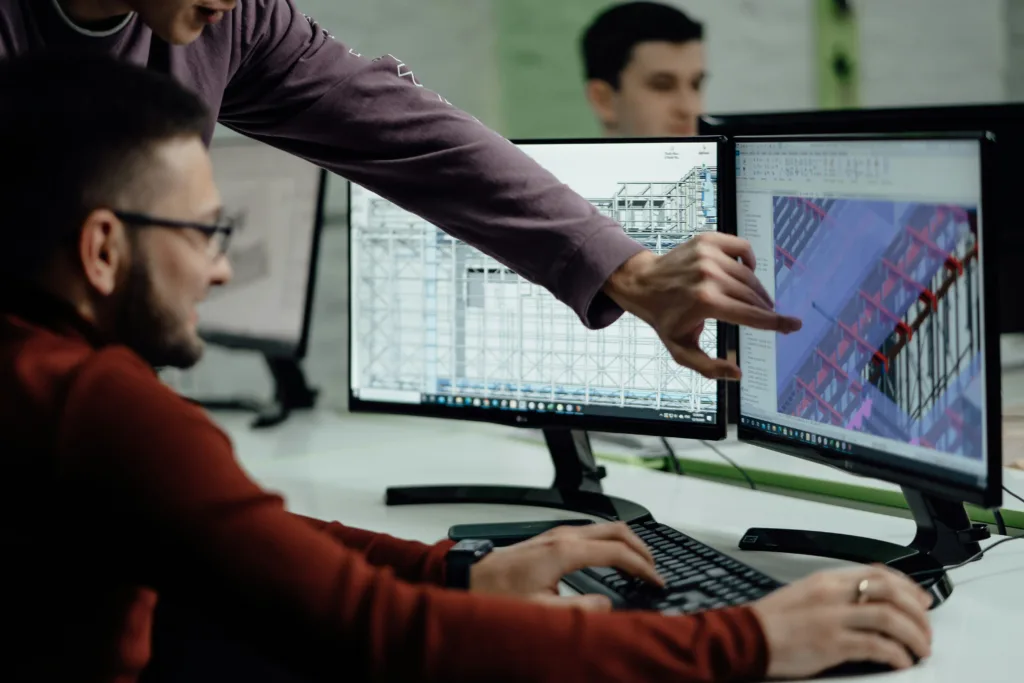

Every project starts with clear communication and drawings. Detailers translate design documents into detailed shop drawings that show exactly how each beam, column, or connection should be fabricated. This includes:

- Dimensions

- Welds and bolts

- Connection details

- Erection sequence

- Material Lists and reports

- CNC files used in automated fabrication

These drawings guide the entire fabrication process, helping to avoid costly field errors.

2. Ordering and Receiving Steel

Once the drawings are approved, fabricators place orders for structural steel. Steel may arrive directly from a mill or a local service center. Upon arrival:

- Materials are inspected

- Each piece is marked with a heat number and job ID for traceability

- Steel is sorted and stored by type and size

3. Cutting to Size

Steel beams, plates, or angles are cut according to the drawings. Depending on the size and thickness, fabricators may use:

- Band saws (for wide flanges and channels)

- CNC plasma or oxy-fuel tables (for plates)

- Shears (for flat bar or small angles)

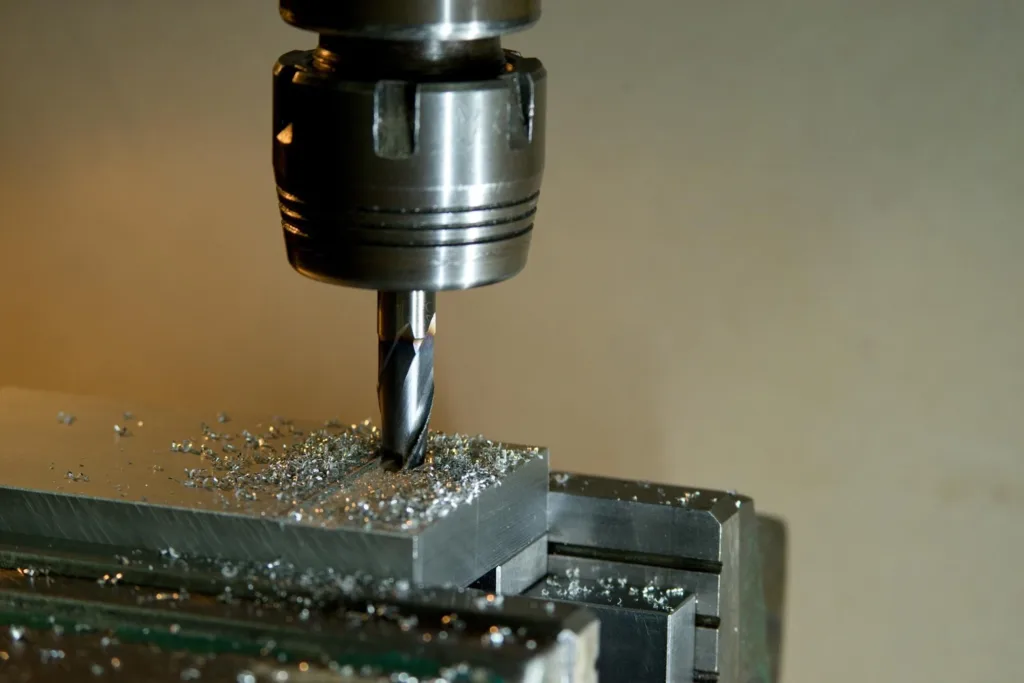

4. Hole Making

After cutting, holes are added for bolted connections. These are made by:

- Drilling (with high-speed drill lines)

- Punching (for angle and flat bar)

- Magnetic drills (for thick or irregular pieces)

- Laser cutting (used for precision holes, especially in plate and thinner sections)

5. Layout and Fitting

Layout crews mark the locations of plates, stiffeners, and clips using soapstone or automated scribing systems. Fitters then place and temporarily attach these components to the main members.

6. Welding or Bolting Components

Fitted parts are either welded (per AWS D1.1 standards) or bolted (per RCSC guidelines). Welders use different techniques based on joint type and load requirements. Bolted assemblies are torqued to specific tension based on the joint classification.

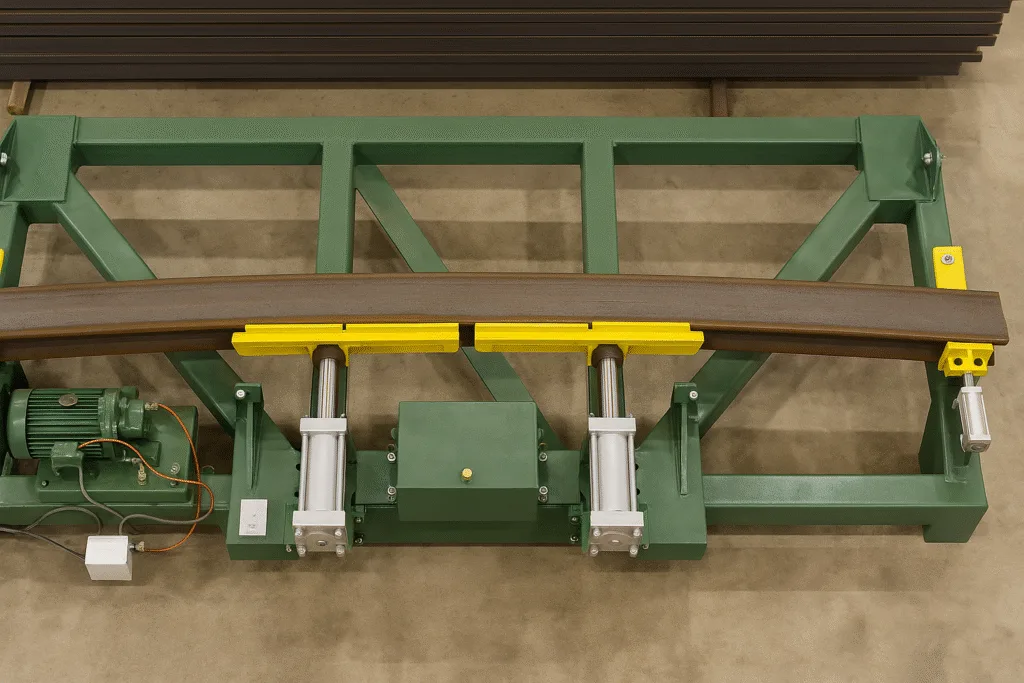

7. Cambering

If the beam needs to be slightly curved to counteract load deflection, fabricators apply:

- Mechanical cambering using hydraulic presses

- Heat cambering by applying localized heating to create a controlled bend

8. Assembly

Some components — like trusses or large assemblies — are pre-assembled in the shop to save time during field erection. This ensures they fit properly and meet shipping limits.

9. Surface Cleaning

Before painting or coating, steel is cleaned using:

- Solvent wipes

- Wire brushing or power tools

- Abrasive blasting (for higher finishes)

10. Coating or Galvanizing

Steel is protected from corrosion by applying:

- Shop primers

- Multi-layer paint systems

- Hot-dip galvanizing

- Thermal metalizing (for complex or oversized pieces)

11. Shipping

Finally, components are labeled, loaded onto flatbed trucks, and secured for delivery. Shipping sizes depend on local road restrictions, and some loads may require permits or escort vehicles.

Why Steel Performs So Well Under Pressure

Beyond being strong and cost-effective, structural steel has physical properties that make it uniquely reliable in demanding construction environments.

Uniform Strength You Can Count On

Steel’s yield stress (the point where it begins to deform permanently) and tensile strength (how much it can be stretched before breaking) are well understood and consistently measurable. Thanks to standardized manufacturing (like ASTM A992 or A36), engineers and fabricators can rely on predictable behavior under heavy loads. This predictability reduces the risk of structural surprises during or after construction.

Ductility That Saves Structures

One of steel’s most critical traits is ductility—its ability to bend or deform under stress without cracking. This characteristic helps structures absorb shocks, vibrations, or even unexpected loads without failing catastrophically. That’s one reason why steel is a top choice in earthquake zones and for bridges.

Elasticity and Recovery

When loads are applied to steel, it first stretches slightly but snaps back to its original form once the stress is removed—up to a certain point. This elasticity gives engineers flexibility in design and lets steel elements handle normal structural shifts or weight variations without damage.

High Performance with Less Material

Thanks to its high strength-to-weight ratio, steel can carry more load using less material compared to concrete or wood. That’s why buildings made with structural steel often have smaller columns, more open space, and greater design flexibility.

Made for Modern Construction

Most structural steel today is produced from recycled material and then alloyed or heat-treated to improve its performance. The result is a material that’s not only strong and versatile, but also sustainable and future-proof. It’s designed to handle both physical forces and the demands of efficient fabrication and installation.

Why Is Steel Detailing Essential for Fabrication?

Steel detailing ensures that the fabricated steel parts fit together exactly as intended. It’s the process where detailers create shop drawings that lay out precisely how each component should be made, assembled, and installed. These drawings ensure every part is fabricated with the correct dimensions, holes, and cutouts—so when everything comes together on-site, it fits perfectly without surprises.

What’s included in structural steel detailing?

Steel detailing includes shop drawings that specify dimensions, holes, welds, and connection material for each part, and erection drawings that show how components fit together on-site. It also covers material reports (like ABMs), CNC and DXF files for automation, and coordination between engineers, fabricators, and erectors. This ensures every piece is fabricated accurately and fits perfectly during installation.

How does detailing affect construction projects?

Investing in steel detailing can help reduce costs and prevent mistakes. It also helps keep everything on track by ensuring that fabrication and assembly processes are efficient and accurate. Without proper detailing, the whole process can become messy, with potential delays and added costs from having to fix mistakes. Steel detailing keeps everything running smoothly from start to finish.

The Importance of Steel Fabricators and Detailing in Construction

Steel fabricators and detailers are essential to the success of any construction project. They’re the ones who transform raw steel into the components that hold the structure together. From creating the detailed drawings that guide the whole fabrication process to crafting precise parts, every step is critical.

By combining hands-on expertise with modern technology, steel fabrication ensures that projects meet deadlines and design standards. Whether it’s a small building or a large skyscraper, steel fabrication and detailing are what ensure the final result is solid, safe, and built to last.

To learn more about the standards and common mistakes in steel detailing that can impact a project, check out this article on steel detailing standards and mistakes.

Need Steel Detailing? Let ESD Solutions Help!

At ESD Solutions, we provide top-notch steel detailing services to ensure your projects go smoothly. Whether it’s a big build or a small one, we’ll make sure everything fits perfectly and meets your specs. Reach out today and let us help bring your project to life!