When you think about steel roof detailing, what comes to mind first? Beams, columns, moment connections, and anchor bolts? Most people picture the big-ticket items—the core of the structure. But here’s a little industry secret: in many projects, especially single-story buildings, the roof can be the most time-consuming, coordination-heavy part of the entire job.

It might seem like just another layer on top, but when you start detailing slopes, joists, roof penetrations, deck supports, and drain frames—all while juggling inputs from structural, architectural, and MEP drawings—you realize this is where the real puzzle begins.

And if even one small piece of that puzzle is off? You’re looking at field issues, delays, rework, and a whole lot of frustration for everyone involved.

Why Steel Roof Detailing Deserves More Attention

A steel roof isn’t just a lid—it’s an active component of the building’s structural system. It handles wind uplift, snow loads, seismic movement, and supports a variety of equipment and penetrations. More than that, it’s a key player in weatherproofing and thermal performance.

Here’s what a well-detailed steel roof contributes:

- Structural Integrity: Transfers lateral and vertical loads, supports RTUs, and handles diaphragm action in seismic zones.

- Durability: Prevents water intrusion, corrosion, and structural fatigue through proper drainage and flashing.

- Energy Efficiency: Coordinates insulation and ventilation paths that directly impact HVAC loads and occupant comfort.

- Compliance: Meets OSHA, IBC, AISC, and SJI standards to ensure safety for installers and users alike.

That’s a lot riding on your roof—literally.

Why Roofs Are So Labor-Intensive in Steel Detailing

If you’ve ever worked on a single-story warehouse or retail space, you’ve probably seen this firsthand: the roof package can make up up to 90% of the entire detailing scope.

Between the slopes, penetrations (RTUs, dunnages, davits, fans, drains), edge conditions, handrails, and access ladders—it’s like solving a Rubik’s Cube in 3D. And since it’s often one of the last things to be reviewed by other trades, late changes are almost guaranteed.

That’s why great roof detailing is about more than just accuracy—it’s about coordination, foresight, and asking the right questions early.

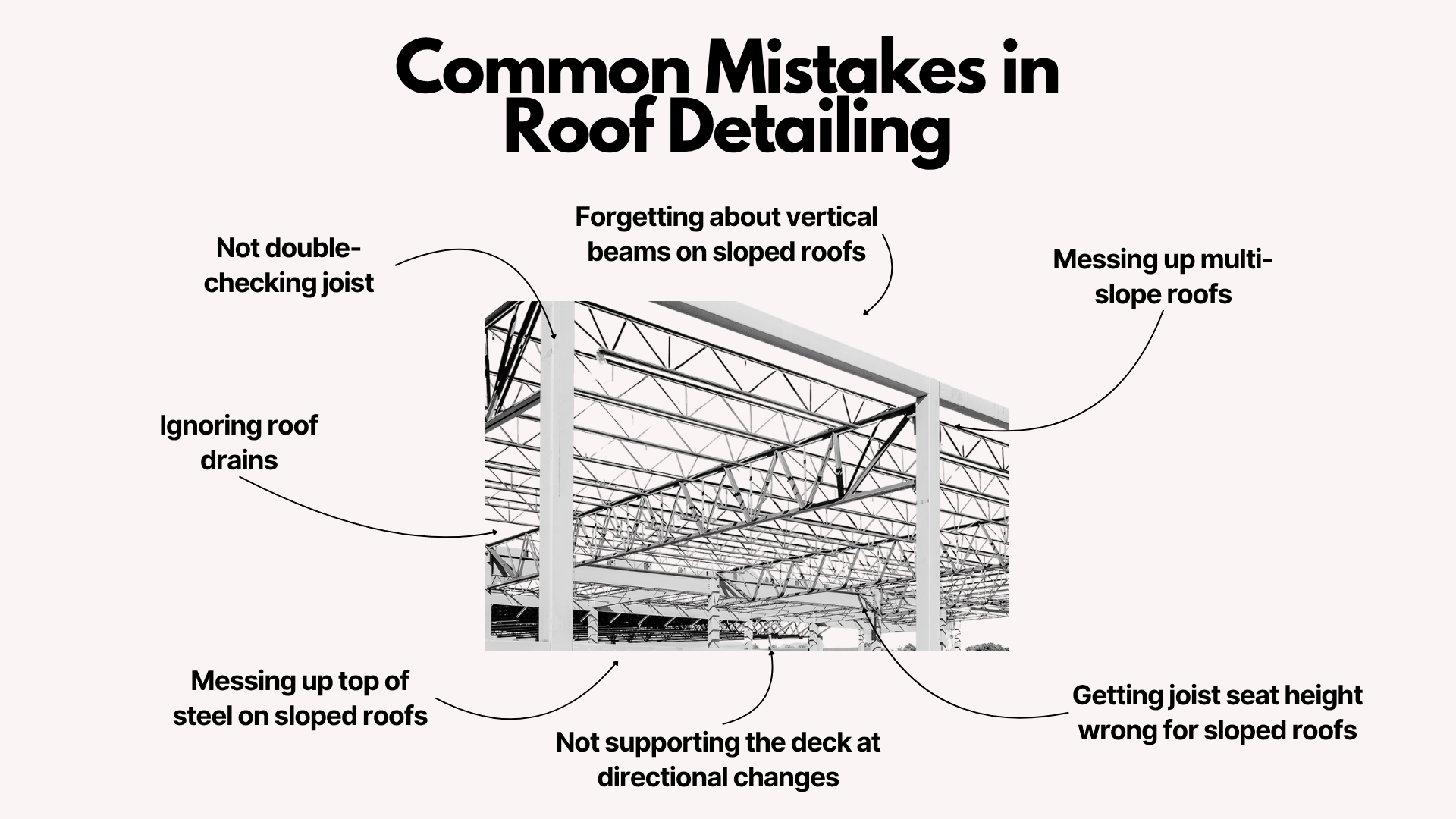

The Most Common Steel Roof Detailing Mistakes (And How to Avoid Them)

Even with the best materials and intentions, roof issues are often caused by overlooked details during modeling and drafting. Below are the top offenders that show up again and again, and how to avoid falling into the same traps.

1. Failing to Coordinate Joist and Deck Drawings

It might sound basic, but it’s one of the most common (and costly) mistakes. If the steel roof framing isn’t aligned with joist and deck shop drawings, you’re asking for problems—misplaced joists, missing bolt holes, wrong seat heights, and time lost to corrections.

What to do:

Before finalizing your roof framing, compare your model to the joist and deck submittals. Pay close attention to seat heights, connections, and deck layout direction. Don’t assume it’ll “just work.”

2. Incorrect Top of Steel (TOS) Elevations on Sloped Roofs

On sloped roofs, even a small error in elevation can throw off the whole system. It’s not unusual for drawings to leave TOS elevations vague or inconsistent between sections.

What to do:

Check elevations carefully. If the drawings are unclear, send an RFI early to get confirmation. Trying to reverse-engineer it from sections may lead to compounding errors, especially when the design drawings are inaccurate.

3. Using the Wrong Joist Seat Height on Sloped Roofs

Unlike flat roofs, sloped configurations require careful calculation of joist seat heights. Guessing or using a default value can result in incorrect bearing elevations and deck misalignment.

What to do:

Always reference the Steel Joist Institute (SJI) Manual for sloped roof applications. Adjust seat heights accordingly and make sure they align with the slope and supporting beams.

4. Misjudging Multi-Slope Roof Geometry

Multi-slope roofs aren’t just about angles—they’re about planes. And when those planes intersect, even one incorrect point can distort the entire model.

What to do:

Start with three non-collinear workpoints for each plane. Double-check intersections with the design team and ensure transitions between slopes are smooth and mathematically valid. Don’t skip this step—it saves hours of rework.

5. Overlooking the Impact of Vertical (Plumb) Beams on Sloped Roofs

Here’s a sneaky one: when the decking is sloped but the intermediate beams are vertical (plumb), you can end up with gaps, kinks, or jogs in the deck layout.

What to do:

Check how the deck sits on every beam—especially filler beams. Use bent plates, wedge shims, or trimmed angles to ensure a smooth decking surface. If in doubt, talk to the deck manufacturer early.

6. Forgetting to Support the Deck when Its Direction Changes

Any time the direction of the deck changes—like at 90° corners, valleys, or hips—it needs dedicated support. Without it, unsupported deck edges can sag, shift, or fail altogether.

What to do:

Use HSS bolsters or bent plates to support deck transitions. And make sure the connection details reflect these items so nobody will miss them.

7. Missing Roof Drains

Roof drains are one of the most frequently missed details. Why? Because they’re often hidden in architectural or MEP drawings, not structural. If you only follow your framing plan, you won’t catch them.

What to do:

Cross-reference all three drawing sets—Structural, Architectural, and MEP—before issuing roof framing. Add support steel, frames, and openings for every drain shown. Trust us, the field team will thank you.

Why Every Roof Detail Matters

In steel roof detailing, precision is what separates a smooth installation from costly field fixes or last-minute rework. When the roof is detailed right the first time, there’s no need for on-site welding, shimmed connections, or refabricating steel. Every seat height, deck edge, and penetration matters—and skipping over the “small stuff” can snowball into severe delays and added costs.

New technologies are helping teams improve accuracy and reduce waste even further. Learn how 3D printing is revolutionizing fabrication in the steel industry and pushing project precision to the next level.

At ESD Solutions, we know that stronger roofs come from smarter detailing. That’s why we focus on getting every detail right—from the first model to the final bolt—so you don’t pay for mistakes later. Ready to take your project from plans to a perfect fit? Let’s talk.