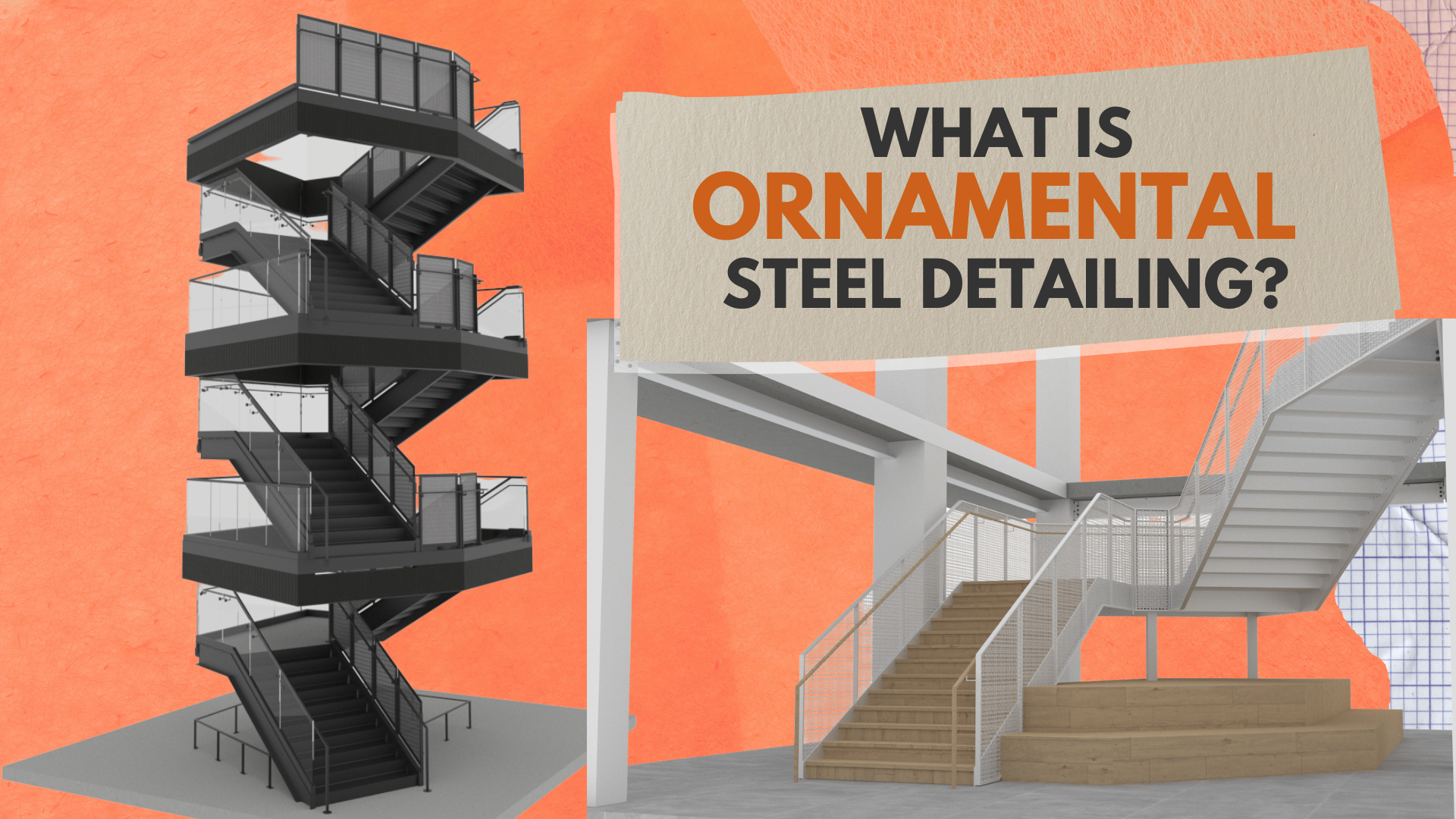

What is ornamental steel detailing? It’s the process of turning bold architectural designs into precise, buildable metal components. Think of sculptural staircases in boutique hotels, minimalist railings in upscale apartments, or sleek canopies over retail storefronts. These aren’t just functional features — they’re focal points.

Unlike structural steel, which is hidden behind walls and floors, ornamental steel is designed to be seen. It’s what people interact with directly. That’s why this type of detailing requires both technical precision and a deep understanding of design intent.

In this article, we’ll walk through what ornamental steel detailing involves, how it differs from other detailing types, and why it’s essential to delivering high-quality architectural results.

Why Ornamental Steel Detailing Matters

Modern ornamental steel components are more than just decoration. They play a crucial role in how people navigate, interact with, and experience a space. Railings ensure safety. Stairs define flow. Canopies provide shelter and design continuity.

But here’s the challenge: architectural drawings often stop at the concept. They show the “what,” not the “how.”

That’s where steel detailers come in. They take initial design sketches and turn them into:

- Accurate 3D models

- Fabrication-ready shop drawings

- Coordinated installation plans

Every connection, angle, weld, and screw must be accounted for — and matched to real-world conditions. Done right, the detailing is almost invisible. Everything fits. Everything aligns. Everything looks effortless.

What Does an Ornamental Steel Detailer Do?

The role goes far beyond creating drawings. Ornamental steel detailers are “technical translators”, ensuring that what’s imagined can be built — and built well.

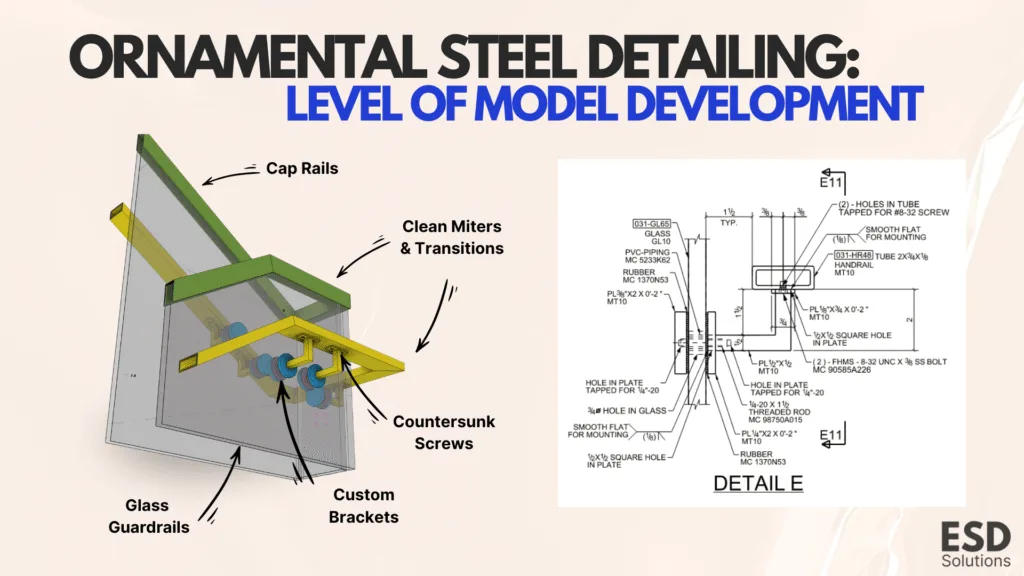

3D Modeling of Each Component

Detailers use software like Tekla Structuresб, SDS2, or Advance Steel to model every part of the system — from stringers and handrails to custom panels and brackets. These models aren’t just visual references; they include:

- Precise geometry and alignment

- Material specifications (plate, tube, pipe, etc.)

- Finishes like powder coat, galvanizing, or brushing

- Fastener types and access clearances

- Fabrication tolerances, especially for field adjustments

The goal is to produce a model that not only looks right but also works in the real world.

Drawing Production

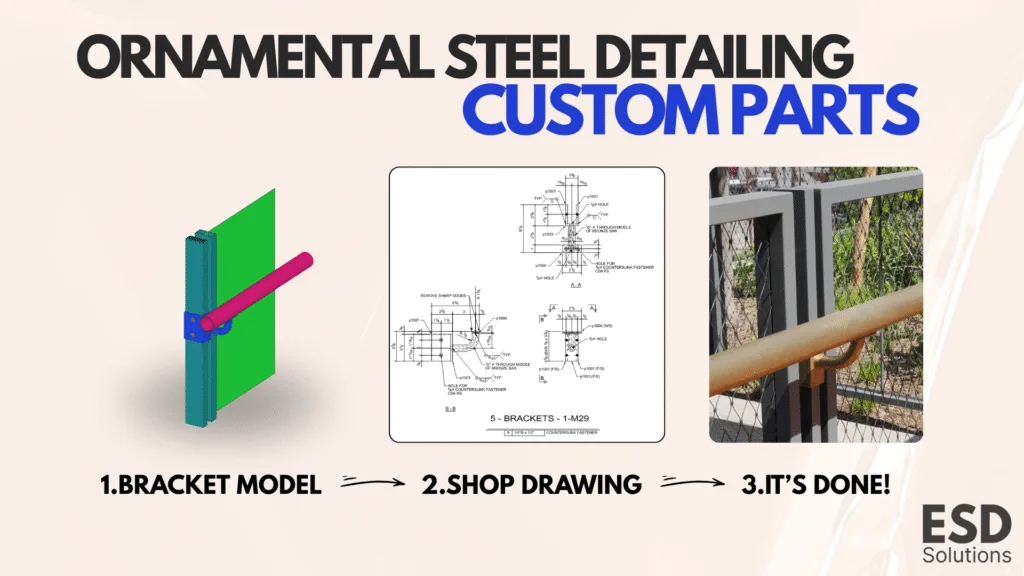

From that model, detailers produce a full drawing package:

- Erection and installation drawings for field crews

- Shop drawings for cutting, welding, and finishing

- Hardware and anchor lists

- Mockups for the architect’s and owner’s review

The drawings guide everyone, from the architect to the welder on the shop floor and the foreman on site.

Coordination and Issue Resolution

Ornamental steel intersects with many trades — millwork, tile, glass, and MEP. That’s why detailers work closely with:

- Architects, to preserve design intent

- Engineers, to meet support and load requirements

- Fabricators, to match shop capabilities

- Installers, to ensure fit and sequence in the field

Detailers also manage numerous RFIs, track design revisions, and flag potential issues before they become expensive mistakes.

A Real Example: Floating Staircase in a Hotel Lobby

Let’s say a project calls for a floating steel staircase with wood treads and a glass-panel railing system. A good detailing team would:

- Align stair geometry with structural and architectural drawings

- Adjust railing posts to avoid lighting clashes

- Refine baseplates to suit finished floor materials

- Add internal stiffeners for glass mounts

- Produce field templates for embedded bolts

- Create install guides to avoid site delays

They would also proactively issue RFIs, resolve any unclear dimensions, and keep drawings updated as the project evolves.

And when the field sends point clouds or redlines? They’ll fine-tune the model to match reality—because in the end, what matters most is what works on site.

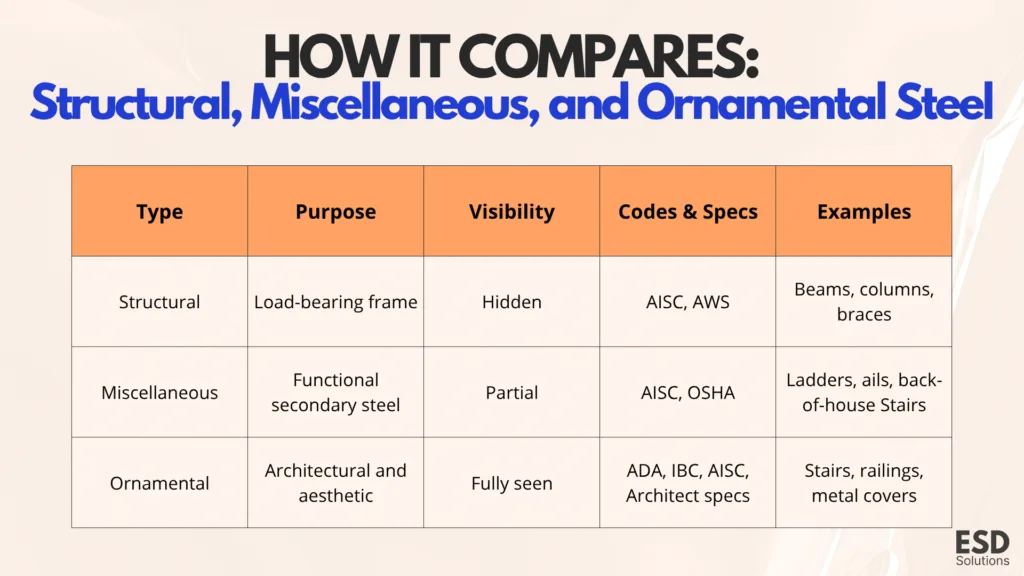

How It Compares: Structural, Miscellaneous, and Ornamental Steel

Want to explore the differences in more detail?

Read:

- What is structural steel detailing?

- What is miscellaneous steel detailing and why it’s more important than you think

Tools and Standards That Guide the Process

Ornamental steel might look like art, but it’s built on standards. Detailers rely on:

Software:

- Tekla Structures — For advanced 3D modeling and coordination

- Autodesk Advance Steel — Useful for stairs, railings, and panel systems

- AutoCAD — For 2D overlays and architectural coordination

- Bluebeam Revu — For markup and RFI tracking

- Navisworks — For clash detection in BIM environments

- SolidWorks — For modeling highly complex custom parts that typical AEC software can’t handle

Codes and Standards:

- AISC Manual — Governs structural and fabrication requirements

- AWS D1.1/D1.3 — Covers weld integrity, including exposed welds

- ADA — Defines accessibility and railing standards

- IBC — Covers stair dimensions, railing height, and guard clearances

- ASTM — Material properties and coatings

- Architectural Specs — Often introduce custom finish or alignment tolerances

These tools and standards don’t just guide the process — they ensure your ornamental steel components are code-compliant, fabrication-ready, and installation-friendly.

Who Relies on Ornamental Steel Detailing?

Fabricators

Use shop drawings and material schedules to cut, weld, and finish parts that must fit without adjustment in the field.

Architects

Expect the detailing to respect their design, maintain visual consistency, and deliver seamless integrations across building elements.

Installers

Rely on part numbers, anchor layouts, and templates to install pieces without last-minute modifications.

General Contractors

Utilize early drawing packages and sequencing plans to maintain crew coordination, resolve issues promptly, and minimize rework.

And others too —

Millwork teams, lighting designers, glazing contractors, signage vendors, and more all interact with ornamental steel.

FAQs About Ornamental Steel Detailing

What is ornamental steel detailing?

It’s the process of developing 3D models and shop drawings for exposed architectural steel elements, ensuring they are safe, compliant, and beautifully executed.

How is it different from structural detailing?

Structural steel is hidden and supports loads. Ornamental steel is exposed and designed for interaction, often requiring tighter tolerances and higher finish quality.

Can’t the fabricator figure it out without detailed drawings?

Usually not. Architectural and structural drawings rarely include the level of detail needed to fabricate ornamental steel — key dimensions, materials, connections, and finishes are often missing. These elements also require coordination with trades like millwork, concrete, and MEP, and many decisions depend on existing field conditions.

What’s included in a typical ornamental detailing set?

- Full 3D model

- Shop and erection drawings

- Hardware lists

- Mock-ups

- CNC/NC files

How early should a detailer get involved?

Ideally, as soon as the architectural layout is ready and structural supports are defined. Early input saves time and cost down the line.

Can it be integrated into BIM?

Absolutely. All 3D models we produce in Tekla or Advance Steel can be exported to Revit/NWC formats for BIM coordination. This is especially useful in tight spaces, multi-trade intersections (lighting, HVAC), and fast-track projects.

Ready to Bring Your Design to Life?

When it comes to architectural steel, detailing is what turns vision into reality. The cleanest installs, the most elegant staircases, the best-aligned railings — all start with solid detailing.

At ESD Solutions, we’ve helped fabricators, architects, and builders deliver hundreds of ornamental steel packages that install clean, pass inspection, and impress the client.

We don’t just model. We plan, coordinate, and deliver drawings that eliminate confusion, reduce delays, and protect your budget.

Explore our ornamental steel detailing portfolio to see real examples of stairs, railings, and architectural steel we’ve helped bring to life.

Let’s talk.

Send us your files — and let’s detail your next ornamental steel project the right way.