So, what is structural steel detailing? It’s the precise, technical process of turning structural design drawings into fabrication-ready instructions and 3D models. It connects architects, engineers, fabricators, and installers by defining exactly how each steel member will be manufactured, assembled, and erected.

Without steel detailing, a structure can’t be built. With it done right, everything fits — down to the last bolt.

In this guide, we’ll break down what steel detailing involves, why it’s essential, how the process works, and what to look for when choosing a detailing company. Whether you’re a fabricator, GC, or engineer, this guide will help you better understand what keeps your steel projects on track.

Why Do We Even Need Structural Steel Detailing?

Structural engineers typically show only the main framing elements, their approximate locations, and often just typical connection details on their drawings. The detailer takes this design and develops it down to the smallest components, accounting not just for the primary steel but also for secondary or auxiliary steel that often isn’t shown on plans and appears only in sections. Connections are fully developed based on the actual layout, member sizes, and elevations, ensuring the design can be accurately fabricated and erected in the field.

Structural steel detailing ensures:

- Fabricators have exact cut lengths, copes, hole patterns, weld types, and BOMs

- Erectors know where each member goes and how it connects

- Coordinated installation with other trades (concrete, MEP, building envelope)

- Fewer RFIs, less rework, and tighter construction schedules

Steel detailing is where design becomes constructible.

What a Steel Detailer Actually Does

Steel detailers act as technical translators between engineers and fabricators. Their main tasks include:

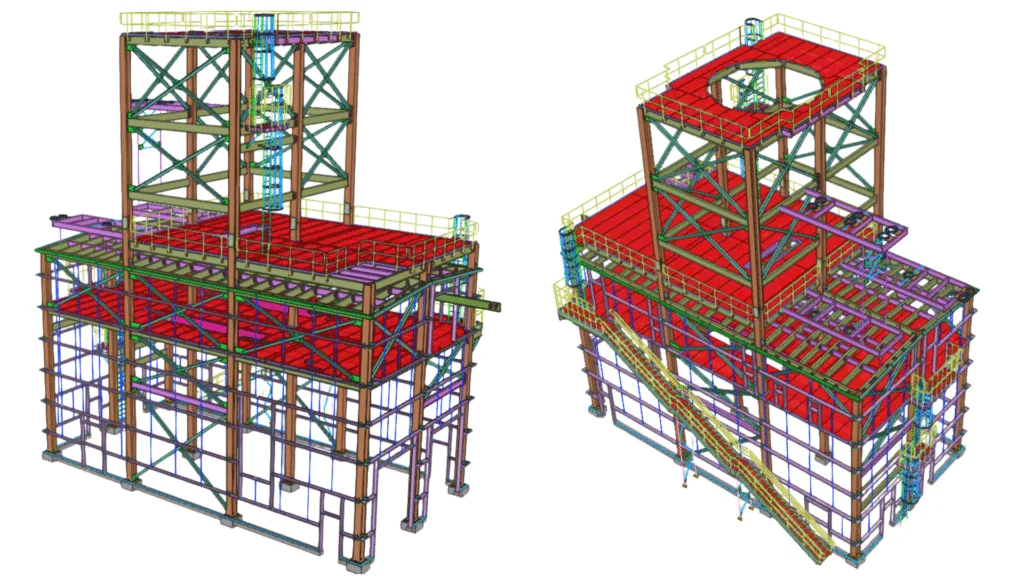

1. Modeling the Steel in 3D

Using software like Tekla Structures, SDS/2, or Advance Steel, detailers create a full 3D model of the entire steel frame — including:

- Primary Structural Items: columns, beams, trusses, braces

- Secondary Structural items: lintels, kickers, edge angles, support frames and many other

- Connection material like shear plates, clip angles, and stiffeners

- Welds, specifies finishes, bolt types, and hole tolerances

This model is data-rich, not just visual. Every part has its own ID and is tied to a specific material specification, member size, weight, finish and other properties.

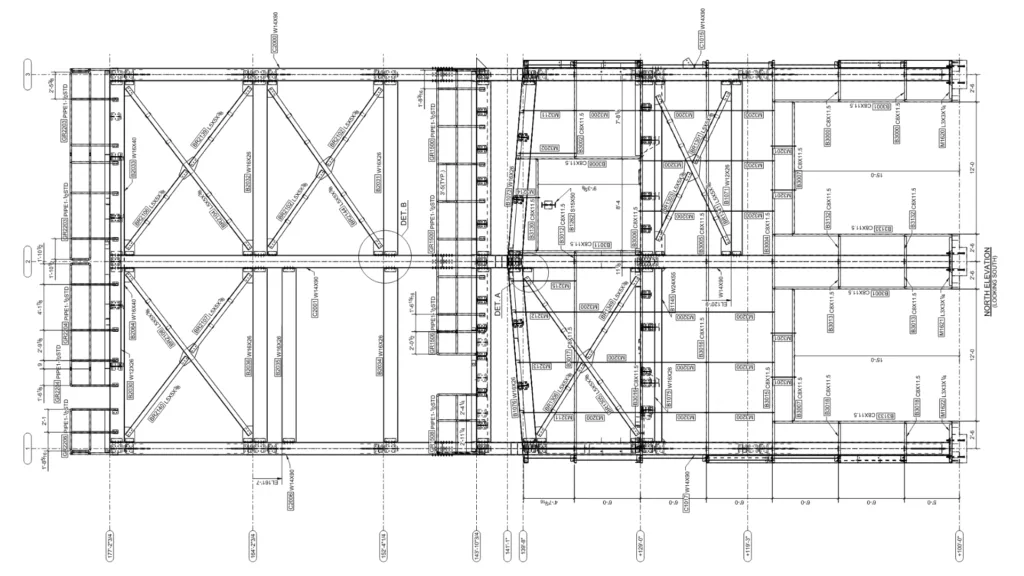

2. Creating Drawings & Reports

From the model, the detailer generates:

- Shop drawings: Used by fabricators to cut, weld, and assemble members

- Erection drawings: Used by field crews to install steel on site

- Anchor bolt and embed plans: Coordinated with concrete teams

- BOMs and NC files: DXF, DSTV, KSS for automated equipment

For a deeper dive into what shop and erection drawings include and how to use them effectively, check out this article on steel shop drawings.

3. Managing RFIs and Revisions

Detailers flag incomplete designs, propose solutions, and coordinate with engineers to resolve:

- Incomplete or conflicting information: framing details, dimensions or elevations

- Changes due to design revisions or site conditions

- Clashes with HVAC, Plumbing or Other Trades

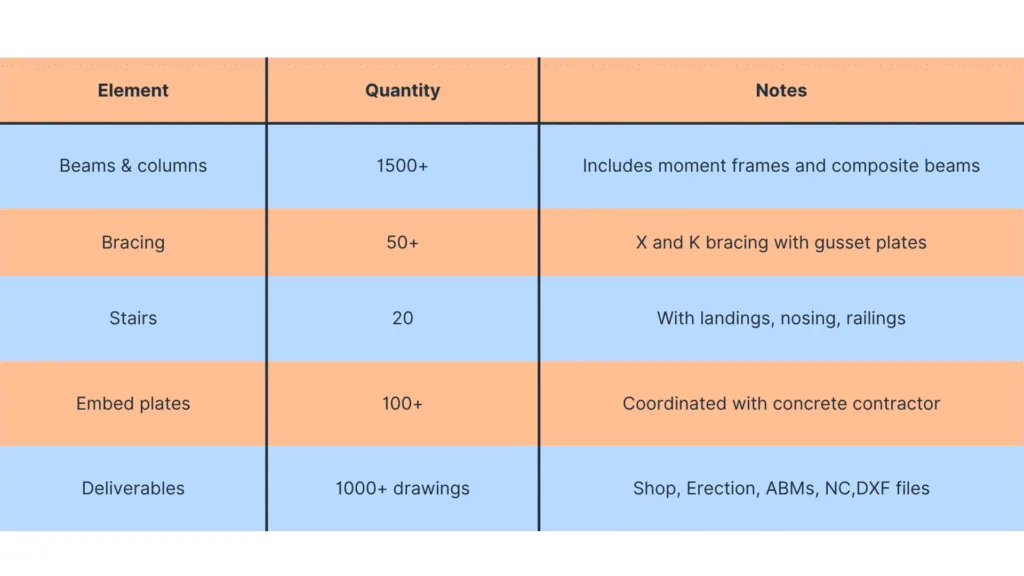

Example: Steel Detailing on a Commercial Building

Let’s say you’re building a 6-story office building. The steel detailer’s scope might include:

Over the course of this project, the detailer may handle:

- 100+ RFIs

- 3 rounds of revisions due to architect changes

- Clash detection with HVAC and MEP shafts

- Fast-track modeling for early procurement of base plates and anchor bolts

Beyond this, detailers often navigate tricky field realities: coordinating with other trades to avoid clashes, adjusting plans for crane picks and site access limitations, and resolving last-minute design changes that can impact connections or member sizes. These challenges can easily stall fabrication if not caught early.

This is where seasoned detailers shine—spotting issues before they hit the shop floor, coordinating with teams, and keeping fabrication moving without delays.

The Structural Steel Detailing Process Step-by-Step

- Kickoff Meeting: Align on scope, milestones, client standards, and submittals

- “Plain Steel” or “Stick” Modeling: Build the core frame based on the engineer’s drawings

- Connection Modeling & Design (if delegated): Coordinate with PE or in-house engineer

- Clash Coordination: Check spatial conflicts in the model

- Create Erection Drawings: Field crew reference with part marks and plans

- Generate Shop Drawings: For fabrication, CNC files, bolt lists

- QA Review: Internal checks and coordination with GC/fabricator

- Submittals & Revisions: Submit for approval, handle revisions, resubmit

- As-Builts & “For Record” Packages: Updated models and drawings post-installation

Each step is backed by communication — detailers constantly check in with engineers, architects, and shop crews & project managers.

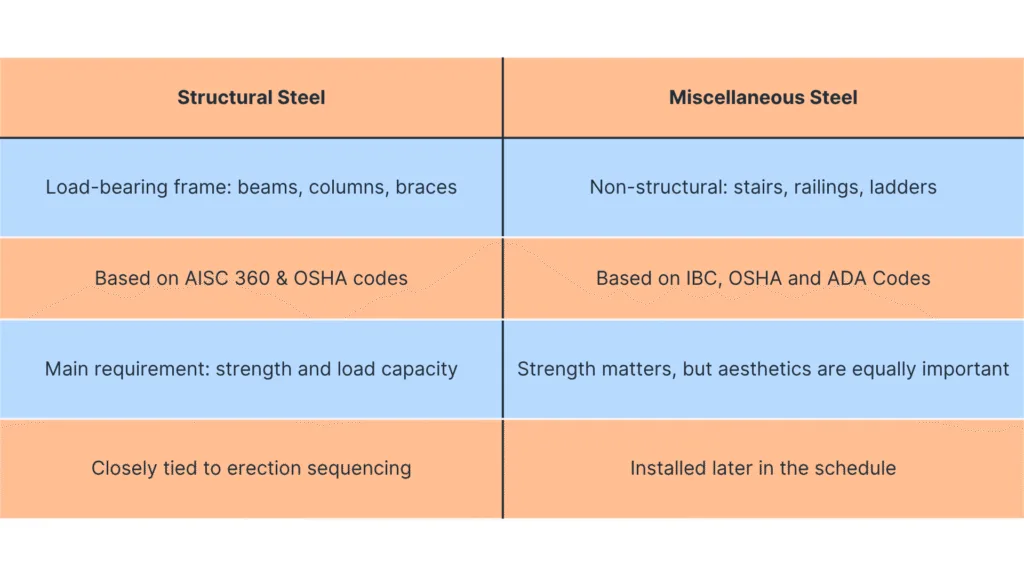

Structural vs. Miscellaneous Steel — What’s the Difference?

Miscellaneous steel detailing involves creating precise, fabrication-ready drawings for non-structural but essential components like stairs, ladders, railings, access platforms, and brackets. These elements may not carry structural loads, but they carry people—and demand the same level of accuracy and coordination as structural steel. Every stair, bracket, or handrail must align with finished floors, walls, and architectural surfaces, leaving no room for guesswork in the field.

To see the difference between structural and miscellaneous steel in real projects, explore our portfolio:

What Makes Steel Detailing Complex?

Even with software, detailing isn’t simple. Common challenges include:

Connection Design Responsibility (CDR):

When engineers delegate connection design to the fabricator, detailers coordinate with a PE to calculate and detail shear, moment, and other connections.

Field Fit Issues:

On retrofit jobs or poorly coordinated sites, detailers:

- Add slotted holes or field welds

- Create shim packs or bolted field adjustments

- Flag potential clashes with existing structures

Fast-Track Projects:

Detailers must phase submissions (e.g., anchor bolts go first) and finalize drawings while construction has already begun. Efficiency, communication, and trust are essential.

Incomplete or Error-Prone Design Drawings:

Design drawings often arrive incomplete or with inconsistencies, requiring detailers to clarify missing information while staying aligned with design intent.

Coordination with Other Trades:

Structural steel detailing requires close coordination with other trades, including HVAC, MEP, and architectural finishes, to avoid conflicts and ensure seamless installation.

Steel detailing demands precision and attention to detail at every step. Each connection, elevation, and piece count matters, and minor oversights can lead to costly delays or field fixes. Getting it right is what makes detailing both challenging and critical for project success.

Software & Standards Detailer Uses

Software Tools:

- Tekla Structures – full 3D model + automation

- SDS/2 – fast modeling with connection tools

- AutoCAD – traditional 2D drawings

- Bluebeam Revu – PDF review & markup

- Navisworks – BIM coordination

Standards:

- AISC Steel Codes & Design Guides

- AWS D1.1 Structural Welding Code

- ASTM (A992, A36, A325, etc.)

- OSHA Safety Standards

- ADA / IBC for stair and railing codes

Who Relies on Steel Detailing?

Steel Fabricators:

Rely on shop drawings, bolt lists, and CNC files to cut, weld, and assemble steel accurately.

General Contractors:

Erection plans and anchor bolt layouts can be used to plan site activities and ensure the steel is installed safely and efficiently.

Engineers:

Review connection details and respond to RFIs to ensure the design intent is maintained throughout the fabrication & erection process.

Architects:

Coordinate stairs, railings, and miscellaneous steel details to align with architectural finishes and accessibility requirements.

Erectors:

Depend on field-ready part marks, piece lists, and clear sequencing to streamline installation and reduce crane time.

Developers and Owners:

Benefit from smoother schedules, fewer delays, and cleaner builds, thanks to accurate detailing that reduces field issues and rework.

FAQs: What Is Structural Steel Detailing?

What is structural steel detailing?

It’s the process of creating shop and erection drawings based on design documents, enabling accurate steel fabrication and erection.

What’s included in a steel detailing package?

3D model, shop drawings, erection drawings, Material and ordering lists, embeds plans, and CNC files.

What software is used in steel detailing?

Tekla Structures, SDS/2, AutoCAD, and Bluebeam Revu are the most common.

Is steel detailing part of BIM?

Yes — modern detailing is fully integrated into BIM workflows for clash detection and coordination.

How long does steel detailing take?

Anywhere from 1–2 weeks for small jobs to several years for large, complex structures.

Why Detailing Is Where the Real Work Begins

Structural steel detailing is more than just drawings — it’s what makes the entire steel structure buildable. Done right, it keeps jobs moving forward, reduces RFIs, and helps avoid costly errors on site.

When you choose the right detailing team, you’re not just getting drawings — you’re getting peace of mind.

Work With Experts in Steel Detailing

At ESD Solutions, we provide high-quality structural steel detailing services for fabricators and builders across the U.S. With 450+ projects completed — from complex stairs to 500-ton structural frames — we deliver detailed models, fabrication-ready drawings, and responsive support.

Need help with a project?

Let’s talk — and get your steel right the first time.